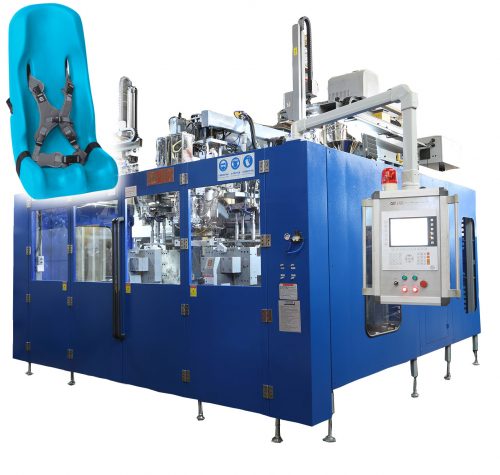

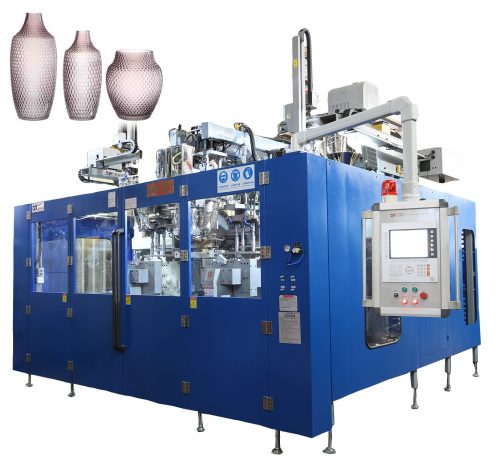

Here’s some production cases on our this extrusion blow molding machine DKB-25LD:

1, Marble crystallizer container

this is for terrazzo and marble floors’ crystallization. Perfect for the crystallization of business premises for its long lasting effect. The container for marble crystallizer is usually jerrycan with handle. Marble crystallizer container with handle is made on extrusion blow molding machine. marble crystallizer container is semi transparent of course.

2, Lubricant oil bottle

Lubricant oil bottle usually got a handle, it is so called jerrycan. 99% lubricating oil bottles are made from Extrusion Blow Molding. extrusion blow molding machine is available for production of any plastic container with handle. Lubricant oil containers jerrycans are usually with with an handle,easy to use in daily life. Lubrican oil bottle can be single layer blow molding or multi-layer co-extrusion blow molding. for multi-layer co-extrusion blow molding, it is purpose to save costs of the bottlle.

3, Liquid laundry detergent container

Laundry detergent is a type of detergent (cleaning agent) used for cleaning dirty laundry (clothes). Laundry detergent is manufactured in powder (washing powder) and liquid form. While powdered and liquid detergents hold roughly equal share of the worldwide laundry detergent market in terms of value, powdered detergents are sold twice as much compared to liquids in terms of volume.

liquid detergents are formulated washing detergents in a liquid form, whereas a powder detergent is formulated in a powder form. Washing powders are generally better at getting rid of mud or clay stains whereas liquid detergents break down oil and grease stains more effectively. Powders have a tendency to leave a residue on clothes whereas liquid detergents don’t because they dissolve better in water.

For liquid detergent container, usually it is a plastic jerrycan with handle. it is made by extrusion blow molding machine.

4, Detergent containers

A detergent is a surfactant or a mixture of surfactants with cleansing properties when in dilute solutions. There are a large variety of detergents, a common family being the alkylbenzene sulfonates, which are soap-like compounds that are more soluble in hard water, because the polar sulfonate (of detergents) is less likely than the polar carboxylate (of soap) to bind to calcium and other ions found in hard water. usually, detergent containers are made by EBM (extrusion blow molding). mostly, detergent containers can be various shapes. detergent container with handle is used for large volume liquid product.

5, Various liquid container

Liquid container can be various, such as Aftabeh, Barrel, Carafe, Decanter, Fuel container, Jerrycan, Jug, Lota (vessel), Oil can, Ibrik, Pitcher (container), Plastic milk container, Portable water tank, Premix and postmix, Square milk jug, Water bottle, Watering can. but plastic liquid containers are made by blow molding mostly.

6, Plastic flower pot

Plastic flower pots are lightweight, strong and flexible—but they don’t have the same durability as resin-based planters. Traditional plastic pots are cheap and widely available at retailers all around the world, hence why they are so common. there are different plastic flower pots, blow molded plastic flower pot and injection molded plastic flower pot. plastic flower port made by blow molding can be 2 layers with hollowed champer, so it can also look three-dimensional and with better out-looking.

7, Various containers

Plastic containers are very lightweight and easy to carry or handle. They are less expensive and portable. Due to the fact that they do not react with the food or substances they contain, plastic containers are utilized as storage devices. So, they are safe and convenient. Plastic containers are usually made by blow molding especially by extrusion blow molding. extrusion blow molding is the only way in blow molding to produce and conainer with handle. this is why extrusion blow molding is so important.

8, Plastic piggy bank

There are plastic piggy bank, cat bank or monkey bank. but plastic piggy bank is most popular. Plastic piggy bank is made by blow molding. plastic piggy bank, plastic cat bank, plastic puppy bank.This plastic animal banks are made by extrusion blow molding for many years.

9, kerosene container

Kerosene container is Featuring a simple spout and flame mitigation device, this product eliminates frustration with an easy-to-use, durable design, and an added layer of protection. kerosene container Kerosene Fuel Can is made by blow molding also. this 5 gallon kerosene fuel can is made on a 100mm screw blow molding machine.

10. Veladoras Quincenales

que es veladoras quincenales Es un tubo de plástico PVC que se utiliza para sujetar veladoras quincenales. Generalmente se produce mediante un proceso de moldeo por soplado. él

11. Vitrolero

Vitrolero – Aguas Frescas Vitrolero de plastico / Plastic Water container 5.25 gal – 20 lts – Vitroleros is a large plastic jar with lid and a Ladle Spoon for containing your favorite cold drink such as: horchata, lemonade, Jamaica drink, etc. Vitrolero or Vitroleros is a large plastic jar with lid for containing your favorite cold drink such as: horchata, lemonade, Jamaica drink, etc. This large vitrolero holds about 5 gallons. The vitrolero is great for party punch. Bitrolero. El vitrolero es un contenedor transparente grande donde se preparan y sirven aguas frescas de diferentes sabores como: jamaica, horchata, tamarindo, melon, pina, naranja, etc. Los vitroleros pueden ser de plastico o vidrio y una vez que se llenan con el agua fresca poniendo muchos hielos que flotan en la parte superior y conservan fria el agua fresca. Se necesita un cucharon largo para poder servir vaso por vaso el agua fresca.

12, Wet issue canister

WetWypes are industrial hand cleaning wipes that remove dirt, grease, grime, oil and paint on the go when soap and water aren’t available. They come packaged in portable dispenser canisters. Each wipe has an abrasive texture that removes dirt and soils without harming your skin. wetwype cainster is made on a blow molding machine also. we issue cainster is the container for wetwypes. it is without handle but better produced on an extrusion blow molding machine.

13,5L sprayer container

Garden sprayer container is made by extrusion blow molding machine. there are 1L hand sprayer, 5L garden sprayer, 20L backpack sprayer. Sprayer container is made with HDPE material and it is easy to produce on extrusion blow molding machine.

The toggle mechanism is highly efficient and yields excellent results; it is widely in the clamping units of injection-molding machines. This work explores the effect of key design parameters – the speed profile of the moving platen, the stroke of the clamping hydraulic cylinder and mold-opening, the ration of force amplification, and the initial angle of mold-closing on the performance of a five-point double-toggle clamping mechanism, drawing on a newly developed formulation of motion.

The toggle mechanism is highly efficient and yields excellent results; it is widely in the clamping units of injection-molding machines. This work explores the effect of key design parameters – the speed profile of the moving platen, the stroke of the clamping hydraulic cylinder and mold-opening, the ration of force amplification, and the initial angle of mold-closing on the performance of a five-point double-toggle clamping mechanism, drawing on a newly developed formulation of motion.