Water bird whistle is that a a whistle shaped in bird. kids blow it then soulds like a bird. if add some water in it, it sounds mostly like from a bird. water bird whistle was made from clay or plastic or other material. normally it can be made by Rotational molding. made by injection molding is also popular. now our DKB-2.5LD produces this transparent waterbird whistle is perfect.

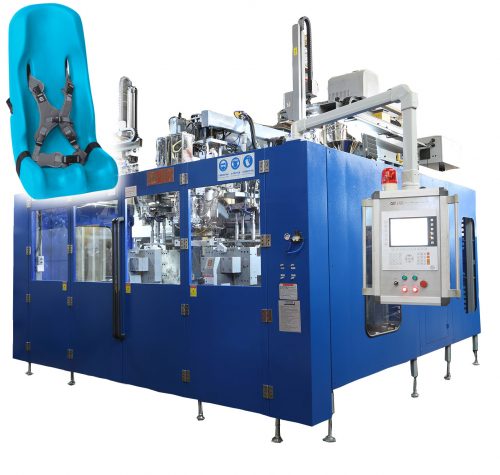

water bird whistle is useful for traning on your baby’s voice function. blow this water bird whistle is working on increasing lung capacity. this transparent water bird whistle is made by extrusion blow molding machine. for this kind of non transparent opaque water bird whistle like this it is also made by extrusion blow molding machine. Our DKB-2.5LD is continuous shuttle type blow molding machine for making plastic hollowed products, such as this kids toy, plastic waterbird whistle.

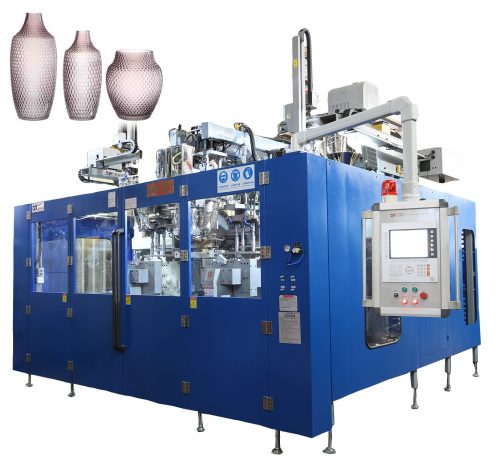

The molding equipment for continuous extrusion blow molding is simple, requires little investment, and is easy to operate. It is a molding method commonly used by

domestic small and medium-sized enterprises.Continuous extrusion blow molding can be achieved with a variety of equipment and operation methods. It includes the extrusion of one or more parisons; the use of more than two molds; the use of more than one mold clamping device; the use of reciprocating, flat turntable, vertical turntable type clamping devices, etc.

Continuous extrusion blow molding is suitable for medium-capacity containers or hollow products, large-volume small containers, PVC, and other heat-sensitive plastic bottles and hollow products.

Medium-capacity containers or hollow products require larger extrusion embryos. The extrusion time of its embryo is also longer, which is beneficial to the extrusion of the embryo and the inflation of the embryo. Cooling and product demoulding are carried out simultaneously, and completed at the same time, to achieve continuous extrusion blow molding. This molding method can continuously blow mold 5-50L containers.

If the plastic material with high melt viscosity and high strength (such as HDPE/HMWHDPE) is used, a larger volume container can be formed due to the improvement of the sagging phenomenon of the mold blank.

Large batches of small containers, such as bottle containers, because of the small amount of parison, the time required to extrude the parison is small. Usually, the

extrusion of the parison and the inflation molding of the parison cannot be completed at the same time. However, when mass production of small containers, the use of two or more molds and mold clamping devices can relatively delay the molding cycle of blow-molded containers to achieve continuous extrusion blow molding.

For hollow products such as PVC and other heat-sensitive plastics, due to the continuous extrusion of the embryo, the residence time of the material in the extrusion process is short and it is not easy to degrade, so the blow molding of PVC and other plastics can be carried out in a long-term and stable manner. This molding method is also suitable for blow molding of LDPE, HDPE, PP, and other plastics.