Hot water bottle is made of rubber usually , it is made on heating sealing machine. The manufacturering process can be divided into the following steps:

- Material selection: The main material of hot water bottles is rubber, which can be natural rubber or synthetic rubber, such as nitrile rubber, chloroprene rubber, etc. The quality, purity, and elasticity of rubber affect the performance and lifespan of hot water bottles.

- Rubber mixing: Rubber needs to be mixed with some additives, such as sulfur, accelerators, antioxidants, etc., to improve the vulcanization effect and anti-aging ability of rubber. The mixing process needs to be done at high temperature and pressure, to make the rubber and additives fully blend. this is done on a rubber rolling mix machine.

- Rubber extrusion: The mixed rubber needs to be extruded through an extruder to form rubber sheets of a certain thickness and width, and then cooled and solidified by a cooling device. The thickness and width of the rubber sheets affect the capacity and shape of hot water bottles. it is done on an extruding machine.

- Rubber cutting: The rubber sheets need to be cut according to the size and style of hot water bottles, forming the upper and lower layers of hot water bottles. The cutting process needs to ensure that the rubber sheets are flat and symmetrical, for the subsequent stitching and molding.

- Rubber stitching: The upper and lower layers of rubber sheets need to be stitched together by a stitching machine, forming the shell of hot water bottles. The stitching process needs to ensure that the rubber sheets are tight and firm, to prevent the hot water bottles from leaking or bursting.

- Rubber molding: The stitched rubber shell needs to be molded by a molding machine, forming the final shape and texture of hot water bottles. The molding process needs to be done at high temperature and pressure, to make the rubber shell fully vulcanized and solidified.

- Rubber inspection: The molded rubber shell needs to be inspected by an inspection machine, checking the appearance, size, thickness, strength, sealing, and other indicators of hot water bottles, to ensure the quality and safety of hot water bottles.

- Rubber assembly: The inspected rubber shell needs to be assembled with other accessories, such as plastic or metal caps, washers, nozzles, etc., to complete the production of hot water bottles.

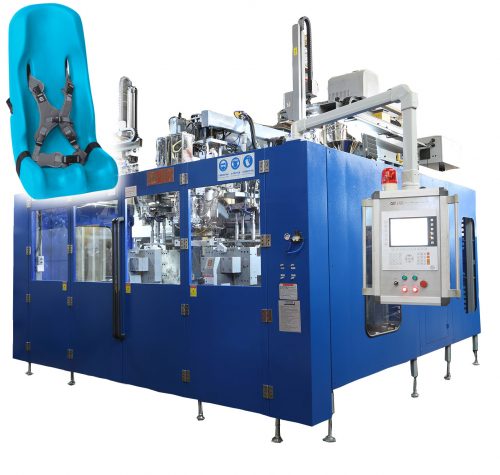

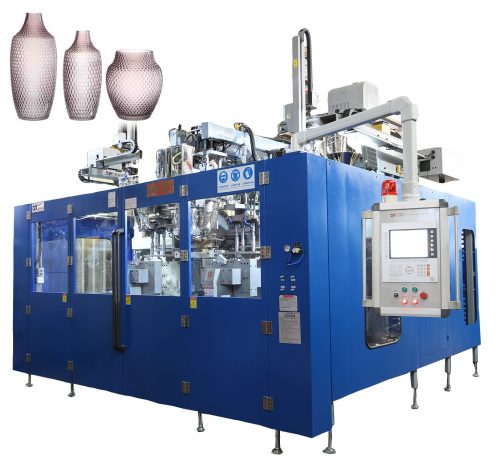

As you see, the manufacturering process is really complicated. there are so many processes on it. Now we create this hot water bottle blow molding machine. To some extent, PVC, TPU,TPE can replace of rubber, we can produce PVC, TPU, TPE hot water bottle on extrusion blow molding machine.

Check this video to know how our blow molding machine produces hot water bottle: