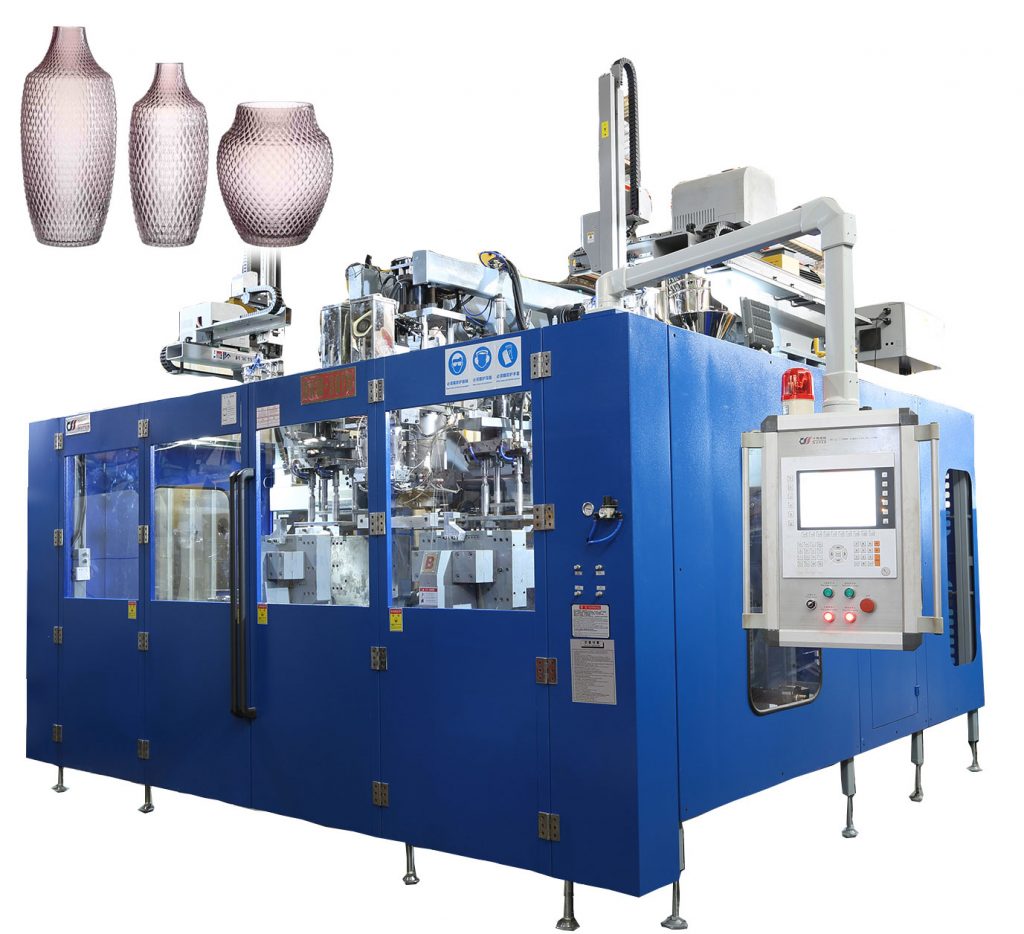

Produce a plastic flower vase using an extrusion blow molding machine. Extrusion blow molding is a manufacturing process that involves creating hollow plastic objects by inflating a hot tube of plastic material, known as a parison, inside a water-cooled mold. The process is similar to blowing up a balloon.

To create a plastic flower vase, the extrusion blow molding machine would need to be equipped with a mold specifically designed for that special designed plastic vase shape. The machine would extrude the molten plastic into a parison, which would then be captured in the mold. Once the mold is closed, air is injected through the top or the neck of the container, expanding the parison and shaping it into the desired shapes.

If you are interested in purchasing an extrusion blow molding machine for producing plastic flower vases. It’s recommended to explore their product offerings and consult with their sales representatives to find a machine that meets your specific requirements.

To create a plastic flower vase on an extrusion blow molding machine, you need an special blow molding machine, as the vase can be quite large in it’s Dimensions, so the mold clamping force should be quite stronge on this extrusion blow molding machine, and also flower vase can be transparent or semi transparent translucent, and with the surface is Very hard to the touch, the perfect material would be PETG, PC, as you know, it is not easy to blow molding on an extrusion blow molding machine.

To create a plastic flower vase, you also need a special mold, remember, it is not normal blow molding, it is special designed for plastic flower vase. normally, as flower vase is with special surface. you can’t take a normal blow mold to produce it, you have to take an special designe mold with unflat parting line blow mold.Plastic vase can be various type, but mostly, all vases are with grace outlook.

Any kind of container can be used for displaying flowers as flower vases, however some are more suitable than others for ensuring good flower development. No matter what the material is, make sure that the container is clean! Our advice: try to display your flowers in Clean and transparent plastic flower vase. Plastic is an inert, hard and smooth material which does not cause a reaction between vase water and vase. such as PETG, PC, PMMA. Plastic is not too sensitive to scratches on the inside and is easy to clean. And it shows the complete bouquet.

Other types of containers can be used, however you could be reducing the vase life of your flowers or even irreparably spoil the container itself!

- Glass are not always resistant to acidic vase water and constant cleaning, glass vase is mostly dangerous when you have kids less than 12 in your home room. because glass vase is absolutely broken when it drops on the floor, and the broked galss is also very danger it cuts into your finger or foot or your skin.

- Crystal, especially when older often has extremely small pores in which micro-organisms can accumulate. These small pores are difficult to clean and make the vase prone to dullness.

- Ceramics are relatively neutral if they are glazed. If they are unglazed, or the glaze is chipped, micro-organisms accumulate in the damaged spot. These are difficult to clean and therefore have a negative effect on the flower’s vase life.

- Metals react with the water. Cut flowers will turn the vase water acidic, just as flower food does. This increases the chance of exchanging metal ions in the vase water. An increased concentration of these metal ions in the water is toxic to flowers and causes burnt leaves and flowers. Always use acid resistant plastic liners in metal containers or vases.