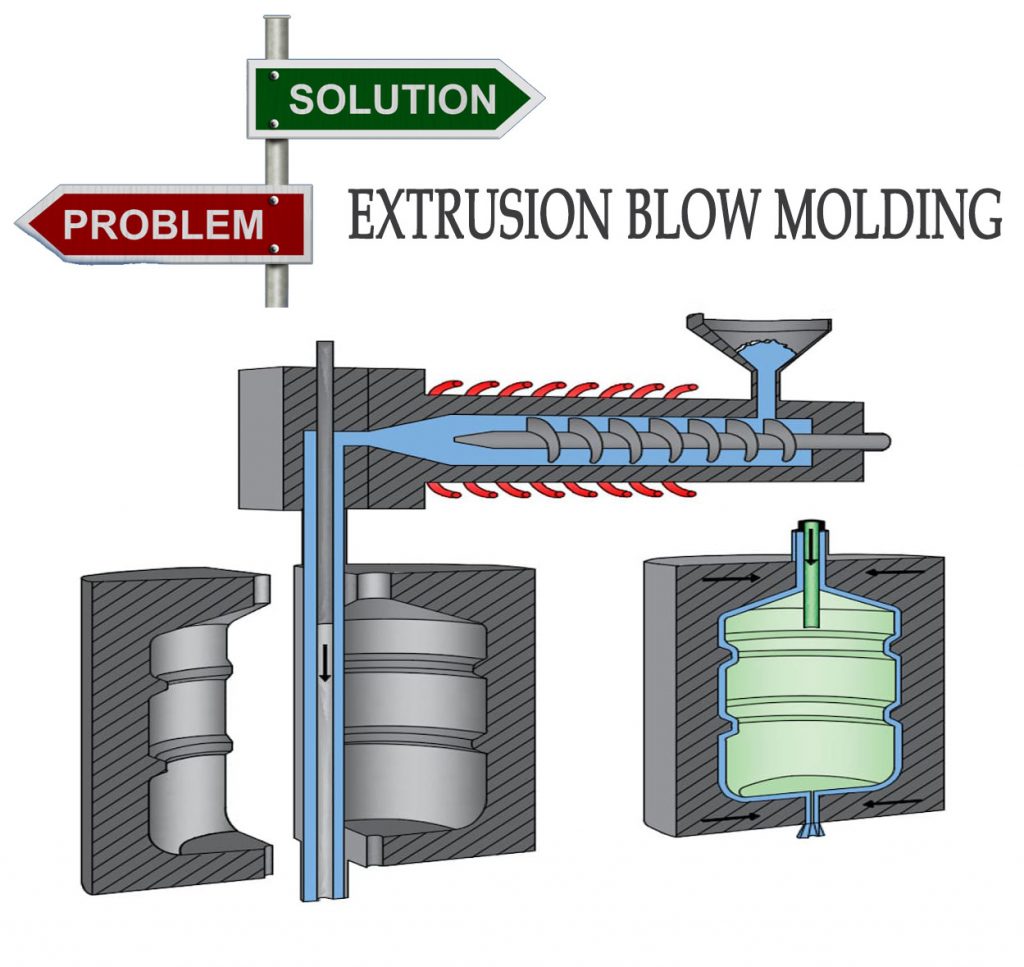

During extrusion blow molding process, some problems always accur whatever you take which brand blow molding machine. this is so called Troubleshooting. here list some common trouble shooting problems and solutions for fixing problems. for deep understanding, here also attached possible causes for this problem.

Bottle Blow-outs

Contamination on the resin is the most reason. Check for contamination in resin and regrinder

Moisture

Check resin for presence of moisture. dry the resin or dehumidificating the material before it goes into hopper.

Bridging in extruder feed section

Bridging in extruder feed section, it is also named sticking material on the feed section. Increase rear barrel zone temperature slightly to prevent voids forming in the melt.

Damaged moulds

Repair mould edges and pinch-offs to prevent holes forming along the seam.

Fill pressure too low (applicable to reciprocating screw blow moudling machines)

To prevent air entrapment, increase fill pressure until drooling occurs at dies, then reduce pressure a little until drooling just stops.

Mould closing speed too fast

Reduce mould closing speed to prevent formation of weak welds at the seams which may split when the bottle is trimmed and/or use clamp pause.

Pinch-off too sharp or too hot

Increase pinch-off land width so that it does not cut parison.

Increase cooling in pinch-off area.

Bottle Volume Bottle weight incorrect

Check bottle weight every hour and maintain to target.

Cycle time

Faster cycle times may increase parison and bottle temperatures and result in greater shrinkage.

High pressure blow psi setting

Should be at recommended setting to insure good contact of parison with the mould surface and consistent cooling.

Poor parison/mould contact

Clean mould vents.

Increase high pressure blow psi setting.

Extruder profile temperature

A higher stock temperature will result in higher parison and bottle temperatures and result in greater shrinkage.

Mould temperature

A higher mould coolant temperature will result in a higher bottle temperature and greater shrinkage.

Storage temperature

Higher ambient bottle storage temperatures and longer storage times will result in greater shrinkage.

Annealing conditions

Higher annealing temperatures and slower belt speeds will result in greater shrinkage.

Mould volume incorrect

Resize mould.

Volume inserts

Install or remove volume inserts.

Bubbles

Moisture in resin, Reduce cooling in feed throat if condensation is occurring here.

Check for moisture in resin and ensure resin handling system is water tight.

Fill pressure too low (applicable to reciprocating screw blow moudling machines)

To prevent air entrapment, increase fill pressure until drooling occurs at dies, then reduce pressure a little until drooling just stops.

Worn screw and/or barrel

Screw and/or barrel may need to be replaced.

Contamination

Dirty regrind Keep contaminants out of regrind; isolate regrind.

Hopper magnets fully loaded

Clean hopper magnets regularly.

Dust Install filters on air intakes and clean regularly.

Die Lines

Contamination or degraded resin Lower mandrel and purge, or if contamination is adhered, remove tooling and clean. Check for foreign matter in virgin resin and in regrind.

Low melt temperature

Check heaters and controllers, adjust so that stock temperature is in the recommended range.

Damaged die or mandrel

Replace tooling if scratches or nicks are present.

Indented Parting Line

Blow air pressure too low Increase blow air pressure.

Air entrapment

Clean mould vents.

Moulds not closing completely Increase clamp pressure.

Reduce blow air pressure.

Check mould alignment or damage that may prevent moulds closing.

Clean mould faces.

Increase preblow cushion time.

Mould temperature too high

Check mould cooling, especially around parting line

Reduce mould temperature.

Melt temperature too high Reduce feed zone temperature

Reduce die tip temperature.

Incorrect bottle weight

Underweight bottles can result in improper shearing and overweight can cause neck finish trimming issues.

Blow pin alignment or damage

Align blow pin centrally and at the correct elevation or replace if damaged.

Damaged shear steels

Replace shear steels.

Damaged pinch-off lands in thread area

Replace pinch-off lands.

Moulds misaligned

Check and replace mould pins and bushings.

Parison Swing or Hooking

Incorrect die adjustment Centre the die and ensure parison bolts are tightened.

Off-centre pressure ring

Centre the pressure ring.

Die temperature variation

Check head and manifold heaters and controllers, ensure die tip heaters are turned off after startup.

Air currents

Shield parisons from air draughts.

Dirty die/mandrel

Clean the die gap.

Melt temperature too low

Increase melt temperature.

Melt temperature too high

Reduce melt temperature.

Mould close speed too fast

Reduce mould close speed; introduce a clamp pause.

Mould temperature too high

Reduce mould temperature.

Pinch lands damaged

Refurbish or replace pinch lands.

Moulds not closing completely

Check mould alignment or damage that may prevent moulds closing.

Clean mould faces.

Flash volume too large or too small

Reduce or increase flash volume.

Excessive preblow or high pressure air too high coming on too early

Reduce preblow air and/or increase blow delay time.

Rough Surface on Bottle

Moisture condensation on moulds Dry the mould cavities or reduce humidity in moulding room.

Blow air pressure too low

Increase blow air pressure.

Check for leakage around neck rings, shear steel and blow pins.

Inspect pneumatic system including air regulator, valves and air filter.

Inadequate mould venting

Inspect and clean or repair mould vents.

Melt temperature too low

Increase melt temperature.

Bottle weight

Ensure weights are adjusted to target. If all bottle weights are varying, check shot pressure and accumulator precharge.

Choke adjustment

Tail lengths can be changed by adjusting the chokes.

Extruder screw rpm

Output is controlled by the screw rpm. Increase speed if tails too short and vice versa.

Barrel and/or screw wear (over-riding temperatures)

Replace barrel and/or screw.

Virgin/regrind ratio and consistency

Ensure consistent blending of virgin and regrind resin.

Surging Check for resin melting in barrel throat and ensure proper cooling.

Incorrect temperature profile

Check heaters and controllers, adjust so that stock temperature is in the recommended range.

Uneven head temperatures

Check temperatures, heaters and controllers.

Incorrect tension in V-belts

Tighten or replace V-belts.

Dirty hydraulic oil filter

Replace oil filter.

Worn seals, excessive oil by-pass in shot cylinder

Replace shot cylinder seals.

Worn thrust bearing centering bushing

Replace the centering bushing.

Webbed Handles

High melt temperature Reduce melt temperature to increase parison swell.

Preblow air pressure too low

Increase preblow air pressure, increase preblow time.

Parisons hooking

Adjust die to straighten parison.

Mandrel sleeve incorrectly positioned

Adjust sleeve to the full up position.

Mould/head alignment incorrect

Realign mould to catch the handle.

Low shot pressure

Check the Manitrol valve for proper setting.

Check the shot cylinder for leaks around seals and rings.

Check hydraulic pump for worn parts.

Check for low charge in nitrogen accumulator – if charge is lost, check for broken or leaking nitrogen bag.

Pneumatics issue

Check that the air lubricator is dispensing the correct amount of oil.

Check that the preblow air regulator diaphragm is not ruptured or has a dirty seat.

Ensure that the Ross valve is clean.

Check for dirt or faulty electrical connection in high/low pressure selector valve spool.