High clarity, easy incorporation of handles, and recycling resin code No. 1 are the principal drivers for converting to EPET resins for extrusion blow molding.

A shifting market preference for extrudable PET (EPET) versus PETG copolyester in order to make extrusion blow molded (EBM) clear bottles that can be recycled with the standard PET stream appears to be gaining momentum. The recycling issue was given a major push by Environmental protection department of all countries in the world.

Another contributing factor is the growing popularity of clear handleware containers, especially for orange and other juices, as well as ready-to-drink (RTD) teas. EBM can mold integral through-handles, unlike stretch-blow molding of conventional PET.

Extrusion blow molding of clear bottles integrating a true through-handle and that can carry the ‘PETE #1’ resin symbol for recycling with PET has long been a packaging goal for consumer-products groups.

One recent success story for EPET has been orange juice, such as Simply Orange, a Coca-Cola Co. brand, which converted from PETG for recyclability. The first big EPET conversion was the 89-oz Tropicana orange-juice jug from Pepsi, which converted, not from PETG, but from white opaque HDPE several years ago in order to take advantage of the crystal clarity of PET. Industry sources also point to EPET conversions from PVC in non-beverage products for improved recyclability.

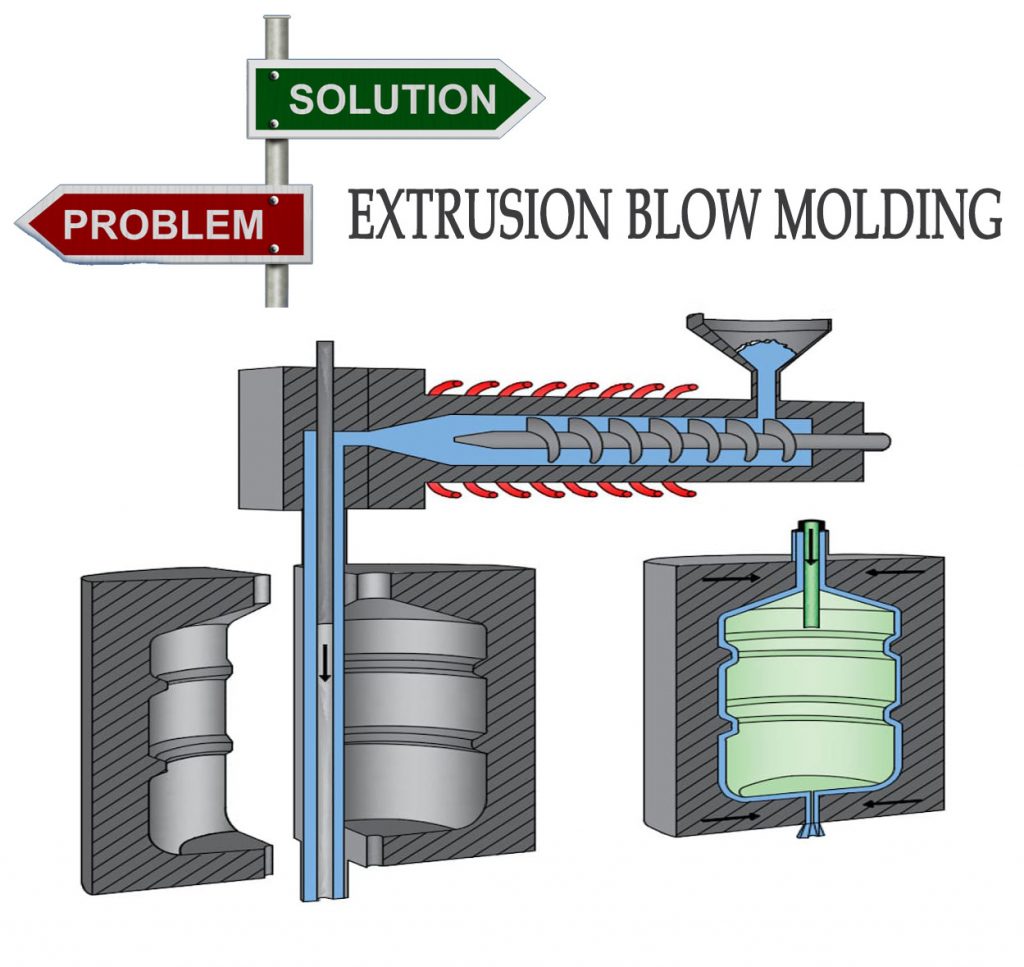

Super Jinjun create a new extrusion blow molding machine special for this EPET or PET containers.