TPV is the abbreviation for thermoplastic vulcanizates. TPVs are elastic and thermoplastic processable materials based mostly on polypropylene and EPDM. They form a subcategory within the general group of thermoplastic elastomers (TPE). The various TPV materials are usually manufactured by reactive extrusion. In the classic case, they consist of the two main components polypropylene (PP) and ethylene-propylene-diene rubber, which are mixed together. The EPDM phase is dynamically vulcanized in this blending process. Due to the adapted shear and mixing forces, the resulting rubber phase is very highly dispersed and distributed within the continuous, thermoplastic phase. In addition, further additives such as UV stabilizers, fillers or color pigments can be added to achieve the desired material properties.

In particular, the mechanical properties of TPV compounds are strongly dependent on the degree of distribution and the size of the vulcanized components.

In addition to the classic design of TPV materials as compounds blends of polypropylene and dynamically crosslinked EPDM, which account for the majority of the total quantity of all TPVs, there are a large number of other material combinations. For example, blends of thermoplastic copolyesters and various dynamically crosslinked rubbers including EVM.

Even as electric vehicles grow in popularity, the existing and new fuel-based vehicles are certainly not going to vanish from the roads anytime soon. They, as well as many industrial machines, require air intake hoses to properly function. Getting the right hose is critical for peak performance, and many times it can be hard to fit inside a tight compartment or connect to two different end sizes. These complex challenges call for customized solutions, and we will help you walk through extrusion blow molding.

Common Air Intake System Components:

- Cold air intake:Inlet for fresh, oxygen-rich air that the engine uses to properly operate and increase horsepower.

- Engine filter:This filter offers clean air to the engine so that the engine functions well even when used continuously. Clean air increases the operational life and reduces wear and tear. On the other hand, if any contaminants enter the engine, it may clog and lead to engine failure. It may also increase the emissions and in turn the environmental footprint.

- Blower:Draws air in through the intake and filter and pushes it into the air intake hose.

- Air intake hose:Transfers filtered air into the engine.

What purpose you want on Air Intake Hoses?

- An air intake hose ensures there is enough clean air and oxygen being supplied to the engine.

- Proper shape or flexibility so that it fits well into the engine compartment while still maintaining good flow characteristics.

- Material that can handle the temperature cycles and exposure to the under-hood environment.

- Minimizes the need for adapter and transition pieces to reduce total assembly time and cost.

- Allows for some vibration isolation to minimize the damage from vibration to sensitive components.

If you are looking for air intake hoses for your air intake system, ensure you source them from experienced manufacturers and suppliers.

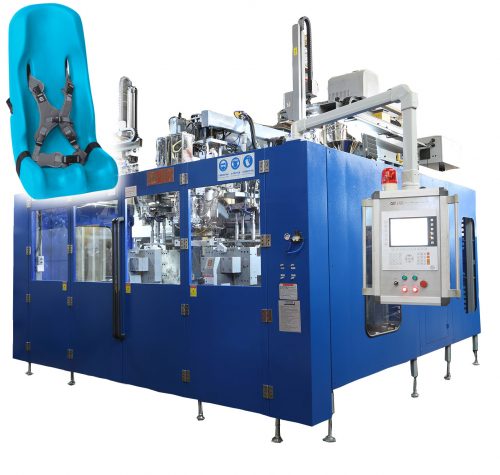

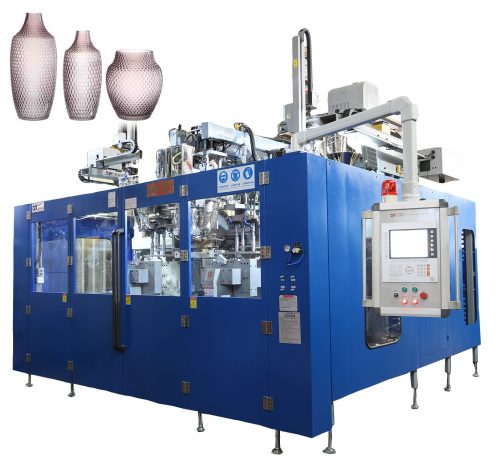

In order to achieve an efficient airflow, the hollow parts therefore often need to have a correspondingly complex design. As a result, blow molding is a very well suited production process for the manufacture of the parts.

Check the video to see how our blow molding machine works on the production of TPE/TPV air intake inlet hose:

https://www.youtube.com/shorts/TDOSn_MXyCM