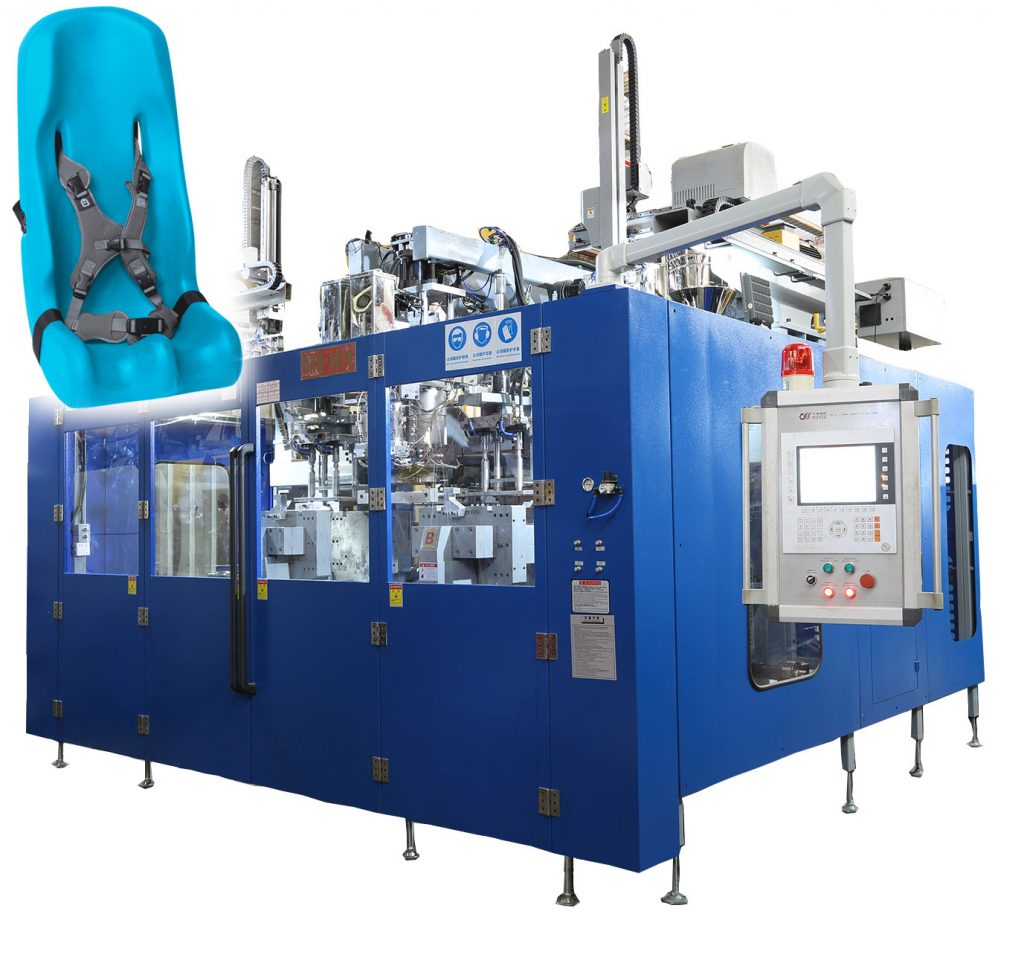

Soft touch plastic baby sitter seat is made by multi layer co-extrusion blow molding machine. soft touch plastic baby sitter seat is actually a normal plastic baby sitter seat but with an special soft touch material on the surface.baby sitter seat can be put in anywhere as this baby sitter. you can put soft touch plastic baby sitter in your home, in a cart, or just in a cart.

soft_touch-sitter-seat at home

Our DKB-25TD extrusion blow molding machine is special designe for this multi-layer baby sitter seat. soft touch plastic baby sitter seat is made by 2 layer or 3 layer co-extrusion blow molding machine. soft touch baby sitter seat is made by Multilayer co-extrusion blow molding.

Multilayer co-extrusion blow molding is the technology of making hollow container by blowing molding.It uses more than two extruders to melt and plasticize the same or different plastics in different extruders.And then compounding, extruding and forming multi-layer concentric composite parison in the die. Its basic process principle is the same as the single-layer blow moulding technique. Only the moulding equipment uses several extruders to plasticize a different kind of plastics.Control the integration and bond quality of plastics layers is the key to the multilayer co-extrusion blow molding technology.

Multilayer co-extrusion blow molding is developed to meet the needs in some industries with some special requirements.

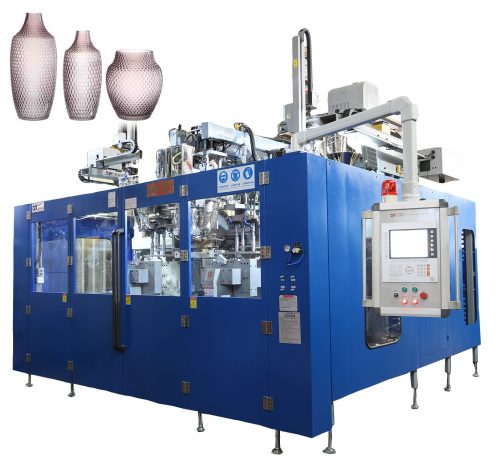

Such as the airtightness and corrosion resistance in pharmaceutical, food, and industry. soft touch cosmetic bottle, liquid food container with barrier layer or chemical container with barrier layer.

Multilayer Co-Extrusion Blow Molding Characteristics

Multilayer co-extrusion blow molding hollow products are produced by extruding several different raw materials into hollow products through multi-layer die head.

To achieve the barrier performance of the container to external substances.

Adopt coextrusion blow molding, compound a variety of polymers together. Forming the multi-layer containers.

The advantages can be summarized as follows:

- Improve the impermeability

- Improve the performance of the products. Such as strength, stiffness, softness, heat resistance, transparency and size stability

- Improve the surface performance of products. No stripe, no speckle, no scratch. More smooth, cleaner.

- Multilayer Co-Extrusion Blow Molding Material Selection

The development of multilayer co-extrusion blow molding technology and equipment makes it possible to choose the best material combination plan.

And this also realizes the production of ideal performance blow molding products.

According to the production capacity range and performance requirements, this technique supports 3-6 layers of production.

Normal extruder and step-less speed regulation of multipurpose dc motor extruder are optionial for Our DKB-25TD Multilayer blow molding machine. The extruder hopper laryngeal is designed for the curve shape. The feed of barrier layer extruder is preheated by temperature control.

Each extruder should be equipped with a torque monitoring device.

The extruders of co-extrusion are operated in parallel and monitored by stages.

The extruders are jointly started. When a certain extruder’s torque drops or feeding interrupts, the whole extruder can stop and act jointly according to the program; the length of parison can be controlled, depending on flow distribution, and can be adjusted automatically and synchronously.

When the melt temperature and torque of each extruder exceed the parallel operation conditions, and when the internal pressure of the bonding layer and barrier layer exceeds the allowable range, the fault display is used to monitor and regulate them. Multilayer co-extrusion die head on DKB-25TD is often designed to patchwork type.

Die head housing consists of several flanged exterior die.

The inner die is assembled by several die cores.

The exterior and interior die pellets are processed accurately, and the runner of the die is polished by chromium plating to reduce the flow resistance of the plastic melt.

The whole machine head is heated by a four-stage adjustable power ceramic heater, which cooperates with the quick start of the machine head and has good heat insulation measures.

Ensure that the die head has the best temperature environment.

The whole machine chooses program logic control or computer control.

The velocity distribution in the opening and closing stages of the die and the moving speed of the blowing foam tube can be controlled by a hydraulic proportional valve and numerical position converter.