The first Kerstbal Christmas ball in the world was created in the 1870s by Germany, it was put on a named ‘Christmas tree’. Christmas ball is one of the Christmas ornaments. Christmas ornaments, baubles, “Christmas bulbs” or “Christmas bubbles” are decoration items, usually to decorate Christmas trees. These decorations may be woven, blown (glass or plastic), molded (ceramic or metal), carved from wood or expanded polystyrene, or made by other techniques.Christmas Ornaments are available in a variety of geometric shapes and image depictions. Kerstbal Christmas Ornaments are almost always reused year after year rather than purchased annually, and family collections often contain a combination of commercially produced ornaments and decorations created by family members.

Commonly,Christmas ball is kind of gilt hanging-thing, There were shining flags and lanterns, and bird-cages, and nests with birds sitting on them, baskets of fruit, gilt apples, and bunches of grapes.

The modern-day mold-blown colored glass Christmas ball was invented in German also in the mid-16th century.The first decorated Christmas trees were adorned with apples, white candy canes, And Christmas balls, hearts and flowers. Glass baubles as the Christmas ball were first made in Germany, The popularity of these decorations grew into the production of glass figures made by highly skilled artisans with clay molds. Glass Christmas ball is expensive with good-quality Christmas ornaments and it is easy broken ,

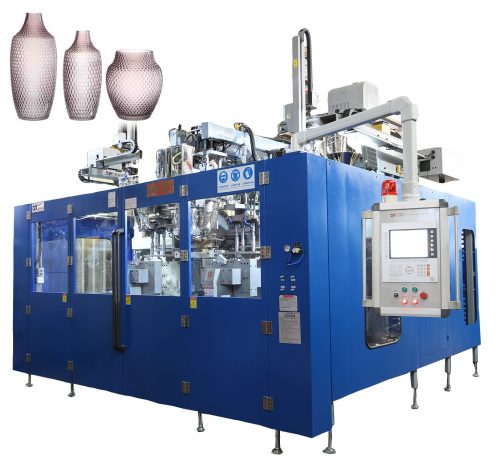

Christmas balls are now frequently made from plastic and available worldwide in a massive variety of shapes, colours and designs. There are a large number of manufacturers producing sophisticated Christmas ball.

People all like this Christmas ball or other christmas ornaments in the world. normally, nowadays Christmas balls are made from

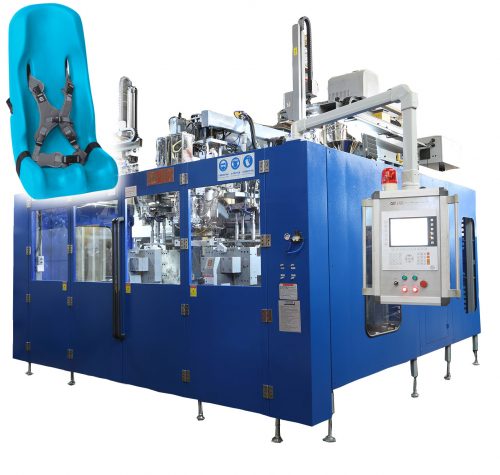

Plastic material. you can take injection molding machine produce 2 hemispheres, then joints them into a Christmas ball. but the best way is you just take extrusion blow molding machine to produce christmas balls. by this way, you can produce any size christmas ball from diameter 3cm to 80cm. A diameter 80 cm Christmas ball Kerstabal is gorgeous and would surprising your guests. Christmas ornaments can be various as the picture.

The use of plastic balls can reduce the use of concrete slabs by up to 30%, while reducing carbon dioxide emissions and using fewer building materials for the purpose of sustainability in the construction industry. Plastic balls using recycled materials, environmentally friendly and durable, the cost and concrete is not far away, there are many countries in use.

The use of plastic balls can reduce the use of concrete slabs by up to 30%, while reducing carbon dioxide emissions and using fewer building materials for the purpose of sustainability in the construction industry. Plastic balls using recycled materials, environmentally friendly and durable, the cost and concrete is not far away, there are many countries in use.