Normally, extrusion blow molding machine is with auto deflash already. but for large plastic container, for example, 25L stackable jerrycan, if auto deflash on the extrusion blow molding machine, that would makes the blow molding machine very big, and It also greatly increases the price of the machine. so, an independent auto deflash device out of blow molding machine is needed.

POST AUTO DEFLASH DEVICE

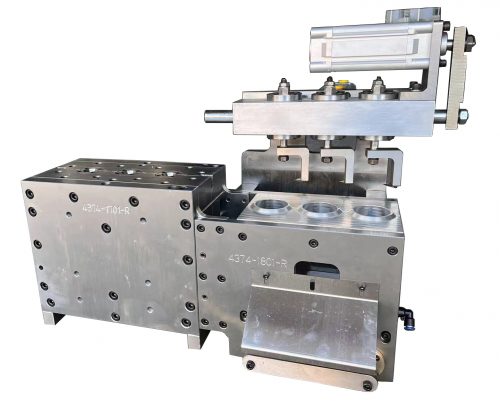

deflashing device is a device that removes excess waste from the mouth and bottom of the product after the product is formed. The deflashing device of the small hollow molding machine is generally mounted on the back plate of the mold, integrated with the mold, or mounted on the machine and separated from the mold. The deflashing device of a large blow molding machine is generally used as an independent auxiliary machine. There are two kinds of de-flashing devices for the mouth, one is to push the flashing edge directly, and the other is to rotate the incision, and the blade is rotated by the mounted blade to cut off the mouth flash.

POST MOUTH TRIMMING DEVICE

usually, most plastic container is with a or several mouths, after deflash, there are always a bit burrs left on the mouth. at this situation, a mouth trimming device is important. after the mouth trimming by this trimming device, the bottle mouth can be very smooth. usually, mouth trimming device is integrated on the post deflash devce. this means, when the plastic container is holded on the post auto deflash devices, it is first under deflashing process, after deflashing, the second process is mouth trimming. after mouth trimming, the plastic container is picked by a manipulator, and placed on the conveyor.

POST CHILLING DEVICE

Post chilling also named post cooling, Post cooling device or postal cooling device is also named post chilling device.

Post-cooling device mold cooling is the most common cooling type for extrusion blow molding. When the parison is inflated in the mold, the melt is pressed against the mold cavity wall, and the heat of the melt passes through the wall of the product and passes through the wall of the mold. The cooling medium is transferred and reduced, and the container is gradually cooled and shaped. The post-cooling device is a device that continuously cools the product after the preliminary cooling of the shaped product is taken out of the mold. This cooling method can reduce the cooling time of the product in the mold, shorten the production cycle and improve the efficiency.

Post-cooling device mold cooling is the most common cooling type for extrusion blow molding. When the parison is inflated in the mold, the melt is pressed against the mold cavity wall, and the heat of the melt passes through the wall of the product and passes through the wall of the mold. The cooling medium is transferred and reduced, and the container is gradually cooled and shaped. The post-cooling device is a device that continuously cools the product after the preliminary cooling of the shaped product is taken out of the mold. This cooling method can reduce the cooling time of the product in the mold, shorten the production cycle and improve the efficiency.

For the actual needs of different products, the post-cooling system can be positioned and fixed-point cooled for different parts of the product (generally higher temperature parts). Cooling sources can also be divided into ordinary and low-temperature sources. For the characteristics of the machine itself, the aftercooling device can be integrated into the device or it can be placed separately as an auxiliary machine. The general small-sized hollow molding machine is mainly integrated after-cooling device, and the large-sized hollow molding machine is mainly composed of a post-column cooling molding device.

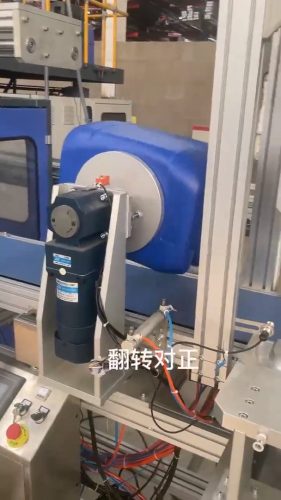

Figure 1 shows a station of an external post-cooling setting device for a 200L barrel. The mouth of the barrel is fitted with a mouth-shaped head to blow the circulating gas into the barrel to achieve the cooling of the barrel and the shaping of the upper and lower ends of the barrel and the barrel. In general, there will be 4-8 such stations in an external post-cooling installation. Controlled by a separate PLC controller, the sound and light will be prompted after the cooling process is completed.

Figure 2 is a schematic view of the integrated cooling device of the small hollow molding machine. The right side is the forming air blowing device, and the left side is the rear cooling device. After the product is clamped by the secondary mold of the mold, it is moved to the rear cooling station on the left side. The cylinder blows the air rod into the mouth of the product to blow the circulating gas to achieve re-cooling of the product.

POSTAL WEIGHING DEVICE

Postal weighing device is to weigh the plastic container , the manipulator puts the plastic container on the conveyor, conveyor transmits the plastic container on the postal weighing device. if the weight of the plastic container is right, then the weighing device let it continue transmiting on the conveyor. if it is not right weight, the plastic container would be kicked out from the production conveyor.

LEAKAGE DETECTING DEVICE

Bottle leak detection equipment provides a solution by quickly and effectively testing bottles for leaks and removing defective bottles from the production line. Leak detection systems can inspect up to several thousand bottles per hour, ranging from small vials to gallon-sized containers.

Features for leakage detecting device:

1.Operates easily: one-botton leaking tests automatically, the text demonstrats leak testing information, the defective products reject the production line automatically.

2. Constructs firmly: The steel plate works fuselage, the fluctuation place unifies the guide pillar and the lead screw.

3. The leak testing precision is high, the speed is quick: using the high accuracy digital pressure sensing index error is to press the leak testing, the laser probe head.

Check this video to see how our postal processing devices works after extrusion blow molding:

https://www.youtube.com/shorts/VcE8Y_R9r4Y