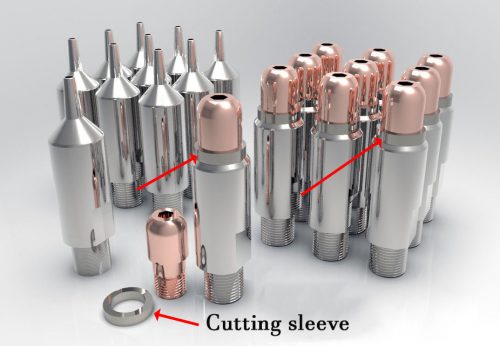

Calibrating blow pin is special blow pin with calibrating and flash waste cutting function.

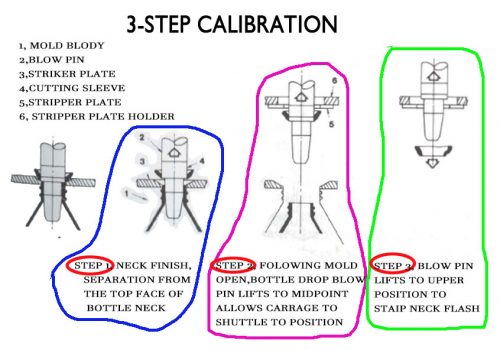

As the pictuere shows. After the parison has been cut off, the blow pin is plunged into the end of the parison to simultaneously( ficture1), force the hot material into the neck ring threads, form the inside diameter and top surface of the neck(step 1), and pinch off the excess plastic above the neck of the container . after this calibrating, you will get the molded bottle with bottle mouth in correct diameter and there is no flash waste on your bottle head.

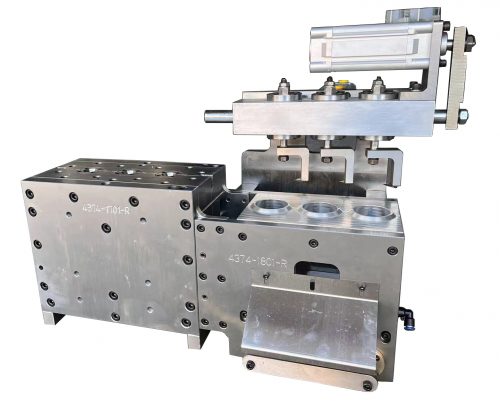

This calibrating blowpin works with A supporting blow mold only. A blow mold for use with the blow pin assembly having article body, neck, and finish defining portions including an anvil portion to permit severing of a flash portion of the parison from the article. A shearing ring portion cooperates with the anvil portion to sever the flash portion of the parison from the article and both portions are inclined with respect to a plane normal to the axis of reciprocation of the blow pin to form an inclined finish on the article. A tip portion has an outer surface cooperating with the finish defining portion to calibrate the thickness of the article between the neck and anvil portions.

By this calibrating blow pin,your blow molding machine would be great improved.the bottle comes from your machine is with stirm neck and the bottle neck is in correct diameter.and you botlte mouth is very good without any flurs . of course, calibration blow pin is also Blow pin. The blow pin inflates the parison with compressed air and forms it into a blown part. After the extruded parison has emerged from the extrusion die in the required length, the blow mold closes, and the parison is cut, normally with a hot knife or spear knife. this is so called blow pin. but our blow pin is with extra function, calibration and flash cutting. this makes it very special.