MOOG servo valves and Servo-Proportional Valves are electrohydraulic, continuously acting valves that transform a changing analog or digital input signal into a stepless hydraulic output (flow or pressure). The term servovalve describes a valve design with bushing spool assembly, characterized by high precision metering edges. The term servo-proportional describes valves with a spool-in-body design.Moog valves provide precise control of position, velocity, pressure and force.

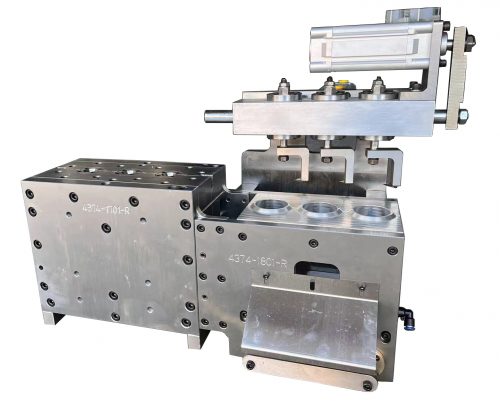

On your blow molding machine, a standard parison thickness controller is needed. it is usually a MOOG parison controller. as you see, MOOG parison controller is drived by hydraulic,To control your parison, with right position, right velocity, right pressure and right force, this Moog servo valve is a must.The servo-driven parison control system for extrusion blow molding machines , all parison controller is designed to adjust the wall thickness of the workpiece by changing the gap between the movable and stationary forming element of the extrusion blow molding machine head.

When setting up a continuous extrusion machine, a time-based program is used. The signal for the beginning of the program cycle sequence is received from the machine (cutting off the workpiece or signal from the photo sensor ), which is also the signal for the end of the previous program cycle. PARISON CONTROLLER measures in each cycle the time interval between two successive slices of the workpiece and distributes the values set from the control panel in the measured time interval at equal intervals . The duration of the intervals for the execution of the program for changing the thickness is determined by the duration of the product manufacturing cycle. Billet wall thickness adjustment is achieved by changing the gap between the movable and fixed shaping element of the extrusion-blowing head of the machine, the exact position of the shaping elements occurs in strict accordance with the specified schedule on the operator panel, which achieves high product repeatability.