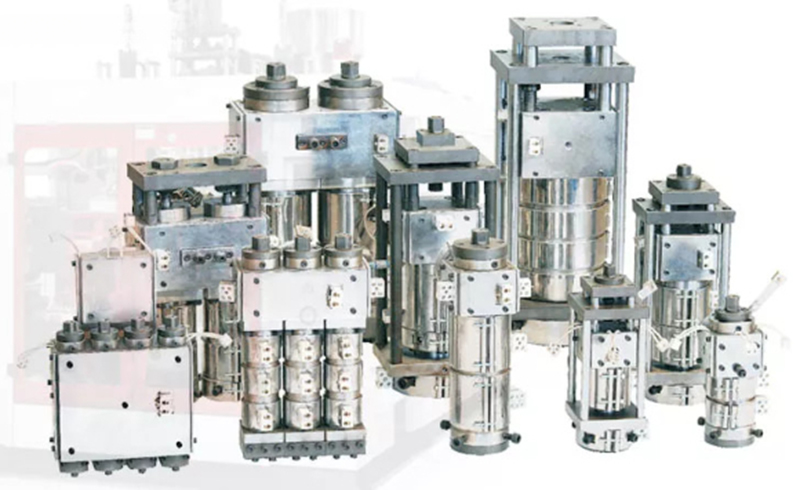

SINGLE OR MULTI-LAYER CO-EXTRUSION BLOW MOLDING DIE HEADS FROM SUPERJINJUN EBM (Extrusion blow molding machine) :

6 layer co-extrusion die head

Automotive spoilers, duct work and reservoirs

Coolers/Chests

Swing sets, slides, bicycles

Medical parts

Housewares

Trash cans

Ornamental packaging

Water coolers and filtration containers

Industrial containers

Panels

Double wall parts

In-Mold Carpet, Vinyl and Component Insertion

Rapid Internal head cleaning

(Disassembly/Reassembly)

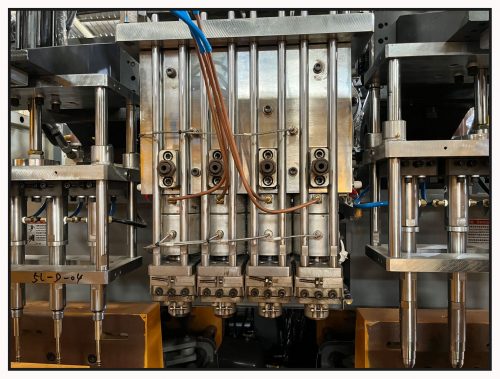

4 die head on blow molding machine

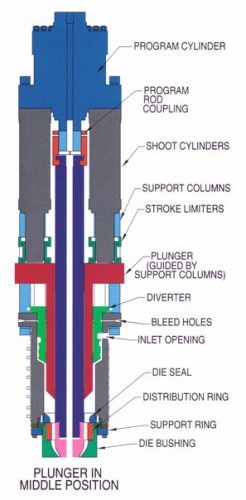

The head can be cleaned within an hour using standard hand tools. No major tools or special devices are required to accomplish this cleaning. The only parts that need to be removed from the machine are two small stroke limiters and a few bolts. On-board hydraulics perform the lifting task

First In-First Out Material Flow

Our uniform flow design eliminates stagnant areas, dead spots and flakes of burnt plastic, which prevents streaks and related defects. Fast and even parison drop and excellent concentricity assure the high quality parts you desire.

Unique flow ring

Wall thickness adjustments for parison curl are performed by four bolts that shift a flow ring in the bushing. The head tooling and program rod itself remain centered to the head.

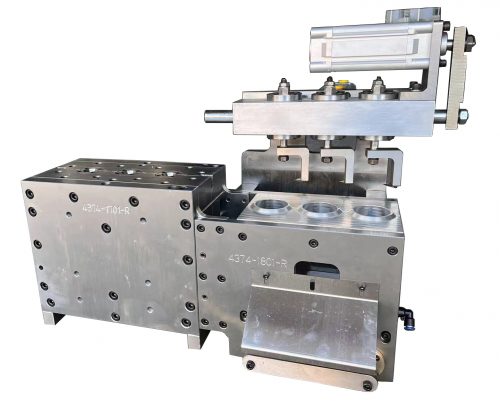

Extrusion System

JINJUN MACHINERY Extruders are designed for maximum efficiency and dependable operation. System features include:

Water cooled grooved feed throat for consistent high output at low melt temperatures