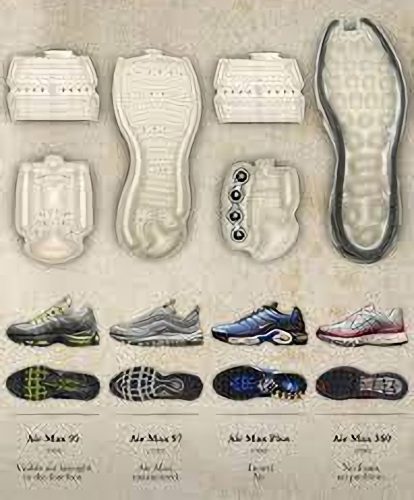

DKB-6TD TPU SHOE AIR-SOLE CUSHION EXTRUSION BLOW MOLDING MACHINE

TPU-air sole cushion from blow molding machine

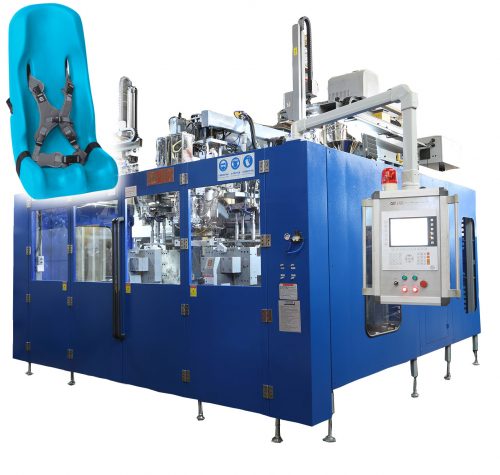

DKB-6LD is normal Shuttle Blow Molding machine. Shuttle blow molding machine are used for the Extrusion Blow Molding (EBM) process. Shuttle machines are either single-sided or dual-sided machines, and can be manufactured to produce one- to six-layer containers for cosmetic, pharmaceutical, food, and chemical applications.

Air-cushioned shoes refer to an air storage cavity between the upper part of the sole and the lower part of the sole. The air storage cavity and the air inlet and outlet channels ventilate each other. The air inlet pores is vertically set at the rear end of the shoe. The air outlet pores are horizontally set on the upper part of the shoe sole.

Thermoplastic polyurethane is a polymer material that has both rubber elastic properties and plastic plasticity. It features with excellent physical properties and mechanical properties, such as high tensile strength and high elongation. Otherwise TPU is also with good resilience and excellent abrasion resistance and puncture resistance, great longitudinal bending strength And high impact strength in low-temperature, good oil resistance and weather resistance. So, TPU is widely used in shoes parts, such as cushion which abrasion resistance and Good resilience is necessary.

Thermoplastic polyurethane stretch tube air cushion mainly used on the heel part, which relies on high resilience performance, excellent puncture resistance, crack growth resistance, and high impact resistance of thermoplastic polyurethane to get a remarkable shock absorption function. Plus, the colorful TPU air cushion let sports shoes get great visual effect.

Polyester Based TPU Material For Footwear

So called “liquid cushion” actually is thermoplastic polyurethane oil-filled air cushion. Mainly function of TPU oil-filled air cushion is absorb shock. It is often used in the heel and waist area to absorb shock and stabilize the turnover of the foot.

Classified by structural

◆ Full palm TPU shoes air cushion: The contour is the same as that of the outsole. The thickness of the air chamber at the edge of the outsole is about 10-20mm, and the wall thickness is 1-1.4mm. It is soft and with high resilience; The air chamber is as a support for the beam; The solid part is as a connection. The entire air cushion is a wedge-shaped structure from the heel to the forefoot.

Full & half palm TPU shoes air cushion

Polyester Based TPU Material For Footwear

◆Half Palm TPU shoes Air Cushion: From the metatarsophalangeal joint to the heel area, the thickness of the air chamber at the waist is the thickest part of the entire air cushion. It has the same design function of the full palm air cushion such as shock absorption and support to stability. The thickness of the air chamber at the waist is 20-25mm, and the heel part is generally 18-20mm.

Polyester Based TPU Material For Footwear

TPU half palm air cushion and TPU full palm air cushion have different requirements for the viscosity of TPU materials. TPU has low viscosity and fluidity is too fast. The production of TPU full palm air cushion with low viscosity will lead the TPU melt sag too fast to fill the full palm. It will resulting in dissatisfaction products and air leakage of the TPU full palm air cushion. Compared with TPU full palm air cushion, the fluidity has less impact on TPU half palm air cushion.

Thermoplastic polyurethane is recyclable. Adding a small amount of recycled TPU to the new TPU granule will not have any impact on the quality of the product. However, please noted that the viscosity of the recycled TPU is relatively low and it reduced every time the TPU is recycled. If the TPU is recycled too too many times, the viscosity of recycle TPU and new TPU granule will be too much difference which is easy to cause pinholes and pimples defects in TPU air cushion.

The main difference between air cushion shoes and ordinary sports shoes is have or haven’t air cushions shoe sole.The air cushion is made of special rebound plastic material TPU, which can effectively absorb part of the reaction force, reduce the burden on the feet, and foot feel more comfortably; the design of the air cushion is to reduce the shock caused by the impact of the ankle and ground impact during daily walking, it can also provide additional shock absorbers and support.

Extrusion blow molding is to clamp the tubular parison which extruded by the extruder into a blow mold in a hot state, and then inject 0.20~0.69MPa compressed air into the parison to expand the tube blank into the cavity shape. Demold the TPU air cushion under pressure.

Due to TPU is easy to absorb moisture and easy to hydrolyze, TPU material without fully dried is hard to processed. The surface of injection products made of unfully dried TPU will have bubbles or silver streaks, and the surface of extruded products made of unfully dried TPU will appear uneven, dull and foam. It is recommended that the TPU raw materials must be fully dried to a moisture content of less than 0.05% before processing. Masterbatch mixed with TPU natural color particles must be fully dried together. Usually, a circulating air dryer or a dehumidifying dryer is used to dry TPU. It is recommended drying about 3 hours under 80-110°C.

Recycled TPU material is available after mixing with new TPU material and must be dried again before use. Recycled materials are not allowed for More than 30% of the overall raw materials in case it affects the mechanical properties of the product. In addition, the recycled material should not be stored for too long time.

Typically used for lower volume output, these machines generally have two to four cavities per mold, positioned horizontally next to each other. Key advantages of the shuttle blow molding process includes:

Typically used for lower volume output, these machines generally have two to four cavities per mold, positioned horizontally next to each other. Key advantages of the shuttle blow molding process includes:

- Low mold cost for low volume output

- Capable of producing high-quality “calibrated neck” finish with blow pins

- In-machine trimming – finished bottles exit the machine

- Capable of producing handleware bottles

- Capable of producing multi-layer bottles (up to 6 layers)

Features for this DKB-6LD:

- Double Station

- Single/Double/Triple/Q.12 Head

- Horizontal Operated Clamping System

- Production Volume:2ml~35L

- Multi layers: Co-Extrusion 1-6 Layers

- Multi cavities: 1~12 cavities

- Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material

- Special function: View Stripe

- Clamping system: Toggle/3 Tie Bar/4 Tie Bar

- Driven Model: Hybrid servo motor drive system/ High performance hydraulic power saving system/Close loop proportional valve

- Support Parison controller/Auto Deflashing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML(in mold labeling)

- Customed for TPU shoe materials, such as Nike air-sole, Nike air max.

Advantages

- Clamp sizes / quantity to match all requirements

- Easily configured for monolayer and multi-layer applications

- Single or multi parison

- Efficient electric drive(s) on extrusion system

- Low profile for ease of operator access

- Part removal and trimming matched to the application

- In-mold labeling and view stripe capable

- Lowest investment cost for high-speed applications

- Extreme bottle quality consistency

- Full automatic production line is optional.

Check this video to see how our TPU air sole blow molding machine works: