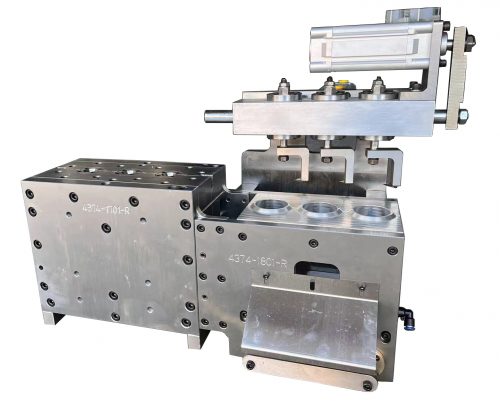

Blow mold on extrusion blow molding machine for plastic bottle containers

For over 20 years, Super Jinjun has been designing, manufacturing, and repairing blow molds for all types of blow mold technologies. We started modestly with a handful of employees who wanted to apply their blow mold industry knowledge to the process of making better tooling.at the begining, super jinjun make blow molds on our extrusion blow molding machine only, but time by time, slowly, now it becomes our another normal contribution for our clients, they buy our blow molds on the machine they bought from us, they also buy our blow molds on the machine from others.

Today Super Jinjun for many of world’s top blow molders. Our team of engineers, programmers, machinists, and tool makers are highly experienced in every phase of building the tooling necessary to produce high quality blow molded parts.

offers custom extrusion blow molding for medical, waste management, automotive, safety equipment, lawn and garden, recreational equipment and large capacity potable water bottles. In our 120,000 sq. ft facility, we produce extrusion blow molding machine, we also produce has blow molds from 1.5 lbs. to 30 lbs. with part size capabilities ranging from 18 grams to 40 pounds and part dimensions as large as 36” by 66”. We have double station shuttle machines with continuous extrusion capabilities as well as an expertise in numerous materials including HDPE, PP, PC, and PETG. As a complement to our blow molding capabilities, we also offer blow mold repairing services.

Super jinjun uses state-of-the-art equipment and technology to produce complete products from concept to sale with unparalleled quality, accuracy and repeatability. As a blow molding machine manufacturing company, we offer custom extrusion blow molding machine expertise, building on the strength of our people, and their dedication to service and quality, our blow molding machine facility encompasses 120,000 sq. ft. including specific areas dedicated to manufacturing, assembly, warehousing, and shipping. We have the experience and expertise to handle unique and demanding projects, and offer a seamless

Super jinjun uses state-of-the-art equipment and technology to produce complete products from concept to sale with unparalleled quality, accuracy and repeatability. As a blow molding machine manufacturing company, we offer custom extrusion blow molding machine expertise, building on the strength of our people, and their dedication to service and quality, our blow molding machine facility encompasses 120,000 sq. ft. including specific areas dedicated to manufacturing, assembly, warehousing, and shipping. We have the experience and expertise to handle unique and demanding projects, and offer a seamless

turnkey solution for blow molding production. Our mold and machine shop capabilities provide customers with a seamless and efficient process from concept to production capability.

Super Jinjun stays ahead of the curve in order to bring new technologies to the markets that we serve and those that we seek to serve. We work closely with customers and technical partners to find the best technologies for goals and challenges facing our dynamic market place.

Extrusion Blow Molding is the simplest type of blow molding. A hot tube of plastic material, called a parison, is dropped from an extruder and captured in a water cooled mold. Once the molds are closed, air is injected through the top or the neck of the container; just as if one were blowing up a balloon. When the hot plastic material is blown up and touches the walls of the mold the material “freezes” and the container now maintains its rigid shape.

For colored bottles, colorants are often fed into the extruder at a controlled rate and mixed with the resin as they are being melted. If barrier and adhesive layers are required, they are fed separately and combined in a co-extrusion head.

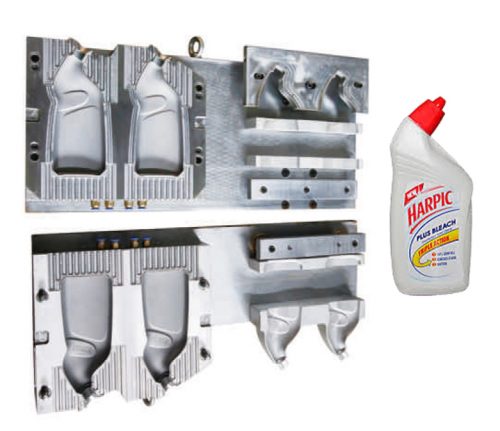

Harpic bottle blow mold

Harpic bottle is widely used on packing of toilet cleaner. as harpic bottle got an angleed neck top, it is not easy produced on normal blow molding machine. it can be produced only on an extrusion blow molding machine and there is an angled blow pin on the EBM machine .for this reason, the blow mold for harpic bottle, it is special designed with angled blowing stairs. as the below picture shows:

angled blow pin on blow molding machine for harpic bottle

Open top single L-ring drum mold

This is blowm mold for 200L top open single L ring drum. as the drum is so big, the weight for the mold is up to 1500 kilogram(1.5 tons). also due to it’s size, it is necessary 40 tons mold clamping force. as the picture shows. we add mold clamping Auxiliary devives on this top open single L ring drum blow mold, it provides about 20 T mold clamping force.

During Sterile Blow Moulding, the blow mold is also with special technology. we talk about sterile blow molding, there are these advantages compares with non sterile blow molding:

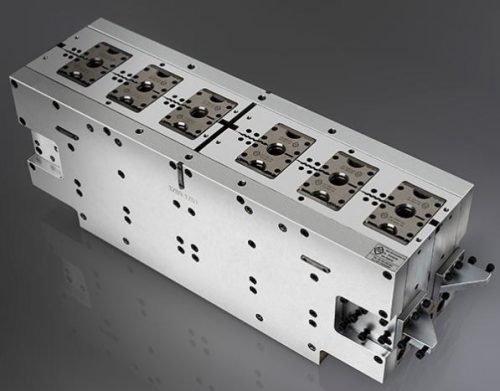

Mold for Sterile Blow Moulding

- The bottle is already sterile at the time it is molded;

- There is no need to use chemical agents that may alter the flavor and organoleptic properties of the content;

- The domo, that is, the part above the neck of the bottle that is sealed, provides a high resistance of the container, which will be useful in case of storage in silos.

The blow mold for sterile blow molding should be sterile itself. during production, when cooling the mold, the cooling medium is needed, cooling medium can be water or air, and yes, the air and the water are also sterile of course.

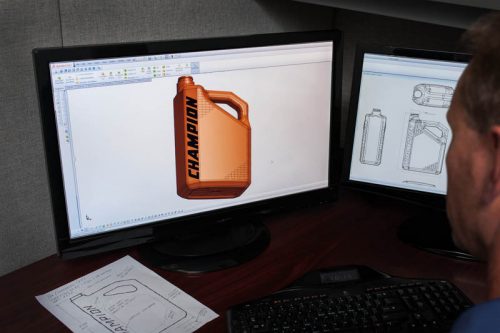

With Creative’s 29 years of knowledge, a 3-D computer design is generated. This 3-D drawing of the new container can be reshaped, redefined, and modified to fit the desired new shape your customer wants and needs for the marketplace. This partnership with the Creative design team can dramatically reduce time to market, since this container can now be manufactured with our state-of-the-art computerized manufacturing, compressing your supply-chain timeframe.

With Creative’s 29 years of knowledge, a 3-D computer design is generated. This 3-D drawing of the new container can be reshaped, redefined, and modified to fit the desired new shape your customer wants and needs for the marketplace. This partnership with the Creative design team can dramatically reduce time to market, since this container can now be manufactured with our state-of-the-art computerized manufacturing, compressing your supply-chain timeframe.