There are 2 types of this plastic bottle bagger machine, full automatic or semi automatic. Full automatic system and semi automatic system. Full automatic bottle bagger takes preformed bag, different bottle with different size, requires different preformed bag.

Full automatic pallet format empty bottle Bagging packing bagger

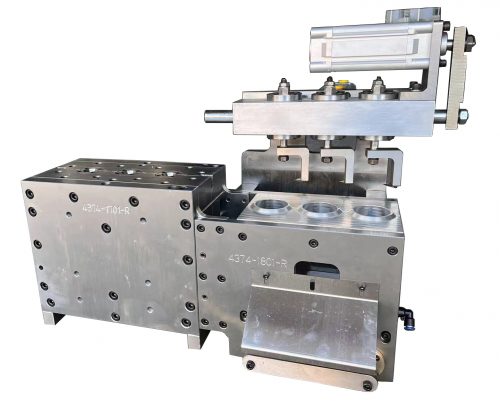

Customized mask per bottle/bag format

Optionally, it allows the packing of bottles into cardboard trays with an open side, integrated in the same machine.

AUTOMATIC SYSTEM VS. SEMI AUTOMATIC SYSTEM

Automatic – Roll of film Semi automatic – Bag pre-formed

Automatic system takes Same roll of film for any bag and bottle size used in the machine.

Semi automatic bottle bagger packaging machine takes preformed bag, Changeover is fast and do not require changing parts.

High autonomy. Give more space for bags accumulation at the output of the machine to gain in autonomy. Every change-over requires a different size/model of preformed bag.

Changeover requires parts changing.

One bag autonomy, as the operator needs to replace the empty bag every time the previous one has been filled and closed.

Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model.

Automatic bagging machine, self-made bag from rolls of thermo-shrinkable film. Compact model.

This equipment is recommended for low cadences and steady bottles.

It is usually installed after the blower and the leak tester.

It arranges automatically bottles and packs them into bags, it has an automatic film supply (from rolls) for the auto-manufacturing of the bag.

The standard equipment allows manufacturing bags of the following sizes: 500×600, 800×600, 400×600, 400×400 (mm)

Super Jinjun’s automatic bottle bagging machines feature their patented Lightning Bars, which improves your plant’s operational efficiencies. An operator can change out the bars, without tools, in less than a minute. Finally, newly-designed Lightning Bars are available for new machines or retrofitted to an existing bagger.

Meanwhile, the Film Tension capabilities on Super Jinjun’s automatic bottle bagging machines are second to none in the industry. Dyco systems bag multiple shapes and sizes of bottles and then provide a tight film wrap around any shape and size. The film tension allows your operation to have neat bundles for easy transport.

CONTAINER TYPES:

Square, Rectangle, Dairy Gallons, Half Gallons

SINGLE INFEED RATE SPEED:

85 BPM Dairy Gallons

DUAL INFEED TYPICAL SPEED:

120 bpm Dairy Gallons, 130 bpm Half Gallon,

130 bpm tall Quart

Ideal for running same container size

Bottle bagger packaging machine is the ability to bag different containers – from separate blow molders – simultaneously. Containers convey or gravity feed into one of two accumulation chambers to make rectangular arrays, which then push into the film for sealing. Once the complete bundle forms, a servo-driven stacker picks up the bundle and gently places it in the stack location.

Check this video to see how Full automatic bottle bagger machine works: