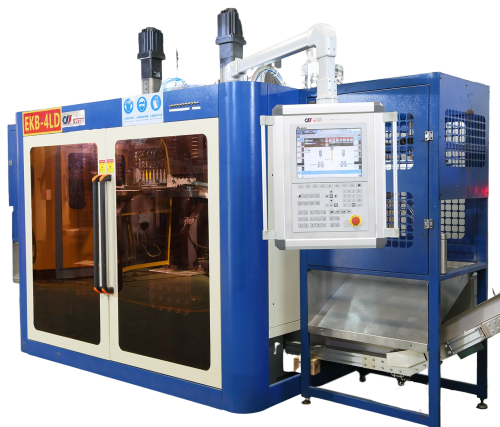

BLOW MOLDING MACHINE WITH 3 LAYER CO-EXTRUSION SYSTEM FOR COSMETIC BOTTLE WITH DEEP GLOSS SURFACE

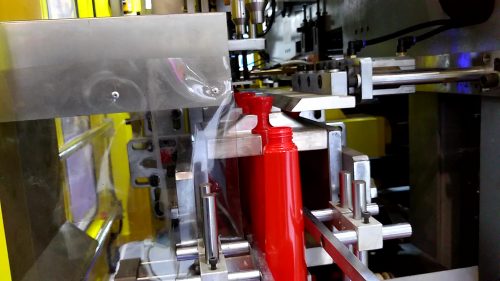

Special co-extrusion Blow Molding Machine For Three-Layer deep gloss surface cosmetic bottles. Normally, EVOH layer is used as a barrier layer for food or medical or cusmetic products packing way. but now we developed a new application for this wonderful material. yes, take 3 layer co-extrusion blow molding machine to produce this cosmetic bottle, the outside layer is this EVOH thin layer. As EVOH is a the plastic material with 100% transparency, and it is natural with smooth surface, so, it looks the bottle color comes from the side, we name it deep gloss. check the picture.

Because this saves you a lot of money. check the follow chart and you will know how it works.

- Double Station

- Single/Double/Triple/Q.12 Head

- Vertical Operated Clamping System

- Production Volume:2ml~5L

- Multi layers: Co-Extrusion 1-3 Layers

- Multi cavities: 1~12 cavities

- Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material

- Clamping system: Toggle/3 Tie Bar/4 Tie Bar

- Driven Model: Hybrid servo motor drive system/ High performance hydraulic power saving system/Close loop proportional valve

- Optional Parison controller/Auto Deflashing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML(in mold labeling)/full automatic production line/leakage tester

Advantages

- Clamp sizes / quantity to match all requirements

Easily configured for monolayer and multi-layer applications

Easily configured for monolayer and multi-layer applications- Single or multi parison

- Efficient electric drive(s) on extrusion system

- Low profile for ease of operator access

- Part removal and trimming matched to the application

- In-mold labeling and view stripe capable

- Lowest investment cost for high-speed applications

- Extreme bottle quality consistency