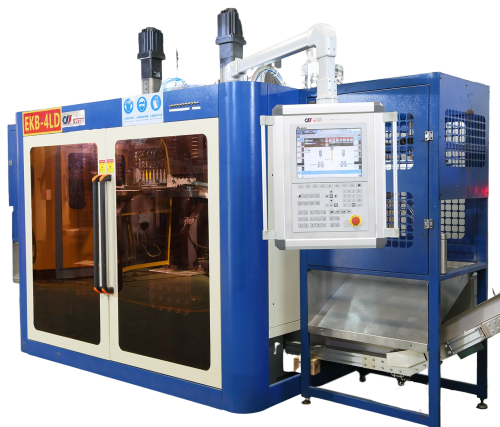

Cubitainers are made from our special designed extrusion blow molding machine with special blow mold. Cubitainers are alternative liquid containers to rigid plastic containers, metal containers, and pails. They can be collapsed for ease of storage.The standard Cubitainer is mono-material, providing a recyclable solution. The advancements of cubitainer as bellowing:

- Cubitainer can be collapsed for ease of storage.

- A chemically-resistant Cubitainer and high gas barrier are available to enable better product protection.

- The inner plastic container uses less material than rigid containers for comparable performance, and the cardboard can be easily recycled.

- Volumes from 1 to 25 liters

- Natural color

- Assembled Cubitainer contains an inflated Cube placed in a corrugated over-pack

- Molded-in handle

- Pull out spout and pour detergents, gels and cleaning products

- Customized cartons

- LDPE insert; fiberboard overpack

- Easy to ship, handle and pour

- Collapsible and lightweight, reduce transportation cost and storage cost

- Liquid flows in continuous stream from self-emptying liner

- Meets FDA specifications

Reagents (hematology), food, industrial chemicals, sodium hypochlorite, liquid processing agents, plating solutions, dairy products, liquors (sake, wine, shochu), liquid seasonings, slurries for semiconductors, resist ink.

The CUBITAINER filling is a simple process. Inflate, fill, and cap.

- Inflation

Inflate the CUBITAINER using low-pressure high-volume air.

The inflation process should take no more than 2 or 3 seconds. - Filling

The reversible neck design requires support during filling. - Capping

There are various filling machines available in the market for this cubitainer, from semi-automated to fully automated machines. If you are thinking about converting from rigid packagings such as a tight head or an open pail to a CUBITAINER, you can potentially modify your current filling machine. contact us give you some good examples of the CUBITAINER filling process.

The cubitainer if made from our extrusion blow molding machine, the material is LDPE+LLDPE.

LDPE Cubitainers are recommended for collecting water samples and other low viscosity liquids to be analyzed for inorganic trace analytes.

- Made of a blend of linear low and low density polyethylene (LDPE)

- Assembled with a 38mm polypropylene screw cap closure.

- Collapsible and nest when empty for efficient storage and transport

- Reversible well design permits the opening to be raised or depressed for pouring and storage.

- Non-glug design assures effluence in a continuous, uninterrupted stream.

- Cubitainers meet UN Packaging Type 4G standard and is authorized for Packaging Group II and III liquids, and conforms to FDA Regulation