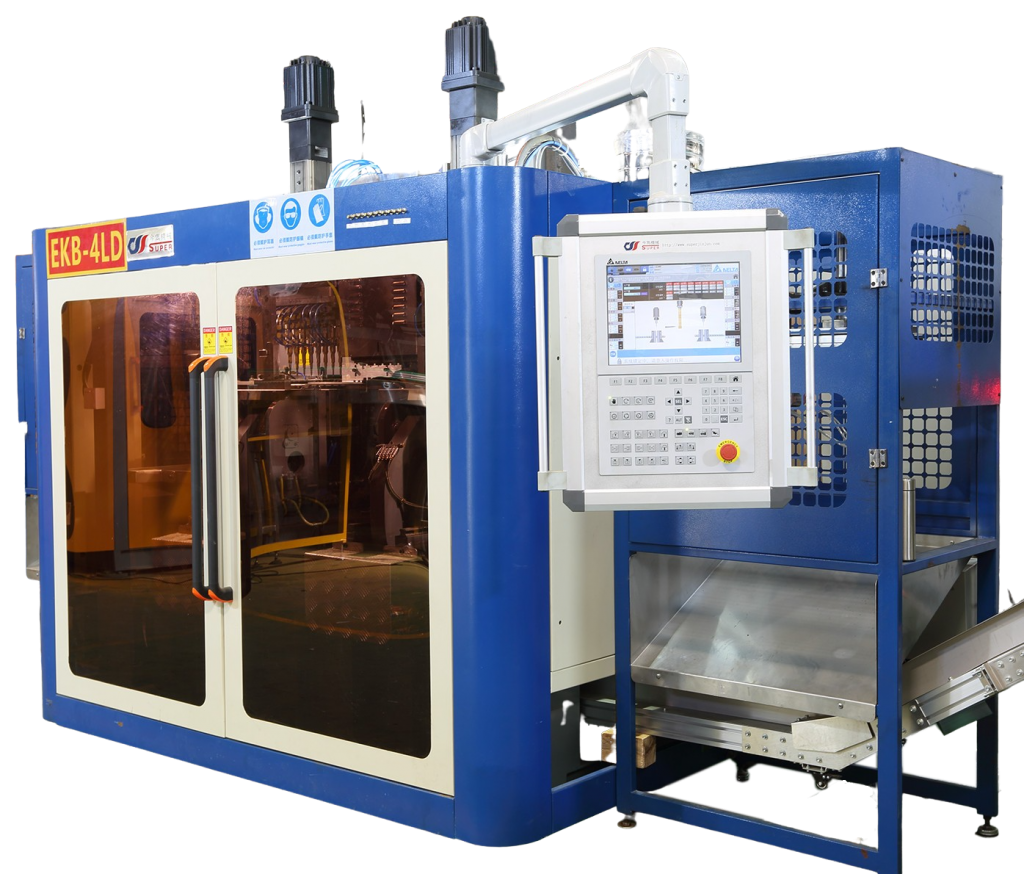

Super jinjun has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is a total new innovative design with servo motors controls which significantly reduce energy consumption, give higher production rate, noise level much reduced, in long term total production cost being dramatically reduced.

This full all electric continuous extrusion blow molding machine is new out of normal hydraulic blow molding machine.

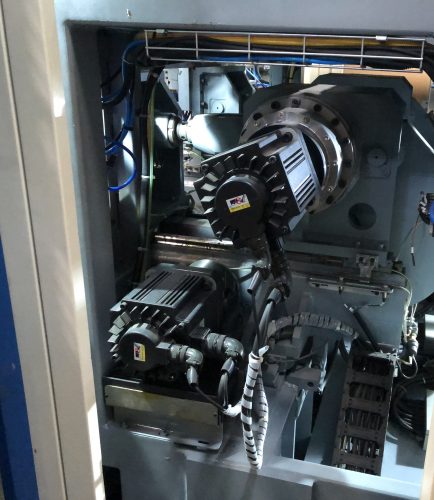

Aview on the inside of all-electric blow molding machine:

inside the all-electric blow molding machine

This full all-electric blow molding machine features Compact structure and reasonable layout. The mold moving stroke 450mm, mold opening and closing 220-450mm, mold clamping force 10 tons.

The height of the mold base from the ground is only 20cm, which is very suitable for manually installing molds, removing molds and changing molds. The originalpatented toggle electric mold clamping system . only SUPER JINJUN has it.

The die head can be single, double, 3 die heads, four die heads until 8 die heads. 8 die heads is very usefull for tiny bottle production less than 100ml.

Operation panel and PLC on this all -electric blow molding machine:

This all-electric blow molding machine is equipped with Delta Programmable logic controller (PLC) and it’s touch screen. Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential/position control, timed counting and input/output control are widely applied to the field of industrial automation control.

The Delta Compact Modular Mid-range PLC AS Series is a high performance multi-purpose controller designed for all kinds of automated equipment. AS series standard CPU features Delta’s self-developed 32-bit SoC CPUs for enhanced execution speed (40 k steps/ms) and supports up to 32 extension modules or up to 1,024 inputs/outputs. It provides accurate positioning control for up to 8 axes via CANopen motion network and max. 6 axes via pulse control (200 kHz). AS series motion CPU features EtherCAT/CANopen motion control interface and multiple communication ports. It also offers motion control function blocks complying with international standards and synchronizes up to 16/24 real axes in one update cycle. AS series controllers are widely used in diverse automated equipment such as packaging, printing, labeling, textile and pharmaceutical industries.

Extruder screw is driven by a servo motor on this all electric blow molding machine

The extrusion machine power on this all-electric blow molding machine is large, so need to be full load in long period, so the motor temperature will be maintained at a high point. Therefore, Fukuta has developed inverter duty motors and induction servo motor, because have forced fan, it does not raise the motor temperature too high due to the speed change, and has stable operating characteristics. It is more recommended to use induction servo motors for high-power options, and High-power induction servo motor is in laminated design. The Insulation is up to H-class and N-class anti-surge copper wire. The product is lightweight, value-added without price increase, to help increase the value of the equipment.

By this serve motor, this full all-electric extrusion blow molding machine works with a pretty low power consumption. if without the servo motor, this full all-electric blow molding machine is with 20kw electric power consumption. But it is about 15 kw electric power consumption.

Guide rail lubricating oil supply system on all electric blow molding machine

Guide rail lubricating oil supply system on full electric blow molding machine

This all-electric blow molding machines took HERG ZH series electric lubricating plunger pump is composed of a micro synchronous motor and a worm gear reduction mechanism. It is a lubricating device that can realize automatic intermittent and oil injection as long as it is connected to the power supply. TM series electric lubricating plunger pumps can be divided into two specifications: 1-3ml/cy and 3-6ml/cy adjustable according to the range of discharge volume.

ZH series electric plunger grease pump can be divided into two types according to the control mode: built-in program controller control and customer PLC control. According to the structure of the fuel tank, it can be divided into two categories: with a dynamic pressure oil pan and without a dynamic pressure oil pan. This type of lubrication pump can be combined with DF series single-line distributor to form a single-line centralized lubrication system. mainly uses NLGI000#~2# grease, application fields: wind power generation, construction machinery, construction machinery and large equipment such as mines, steel mills, metallurgy, and docks. Among them: the lubricating pump without a follower oil plate is only suitable for vertical installation, and the lube pump with a follower oil plate can be installed in any position.