Blowing machine is an indispensable role in modern industrial production, and blowing efficiency has been widely concerned. As a blow molding machine manufacturer, we will explain in detail the following factors that affect the blowing efficiency of the blow molding machine:

● The quality of the preform, including the design of the preform, the dimensional accuracy, and the uniformity of the wall thickness;

● perform a heating system for the blow moulding machine;

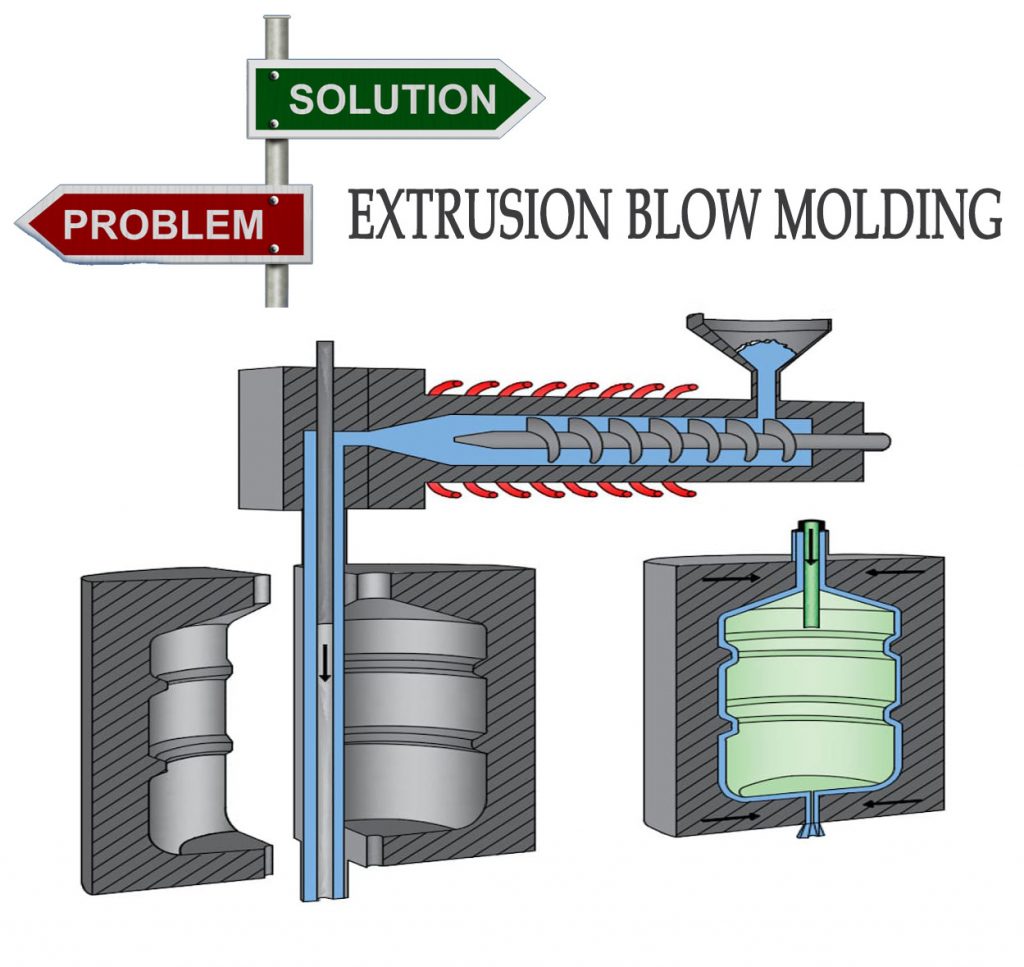

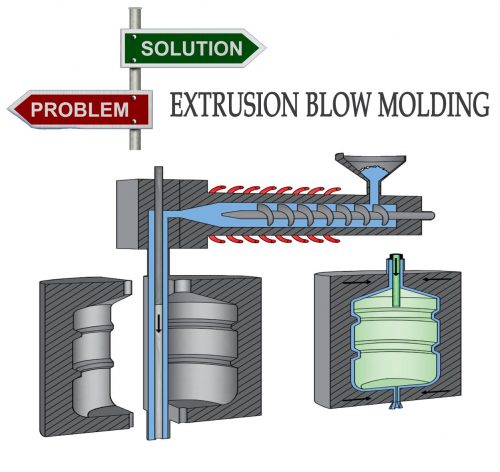

● preform stretching and blow moulding systems for blow molding machines;

● Bottle mould and clamping system.

One of the main factors affecting the efficiency of PET bottle blowing is the solenoid valve. The accuracy, reaction time and life of the blower solenoid valve are very important for increasing the yield of a single chamber. Our company uses the solenoid valve specially designed for us by NORGREN. Because the piston part of the valve is fully hard sealed, the reaction time precision is up to one thousandth of a second and the life is up to 50 million times, thus ensuring the high blow molding machine. effectiveness. In addition, another major factor affecting the blowing efficiency is the machining level and assembly accuracy of the machine. Only high-precision parts and rigorous assembly can create a stable high-speed blow molding machine. The key to improving the “two-step” & device productivity is:

● Optimize the preform heating system to reduce heating time

● Improve the operation speed of the preform

● Improve the performance of rapid and stable positioning of preforms;

● Shorten the opening and closing of the mold and the lifting time of the blow molding head;

● Increase the number of molding cavities.