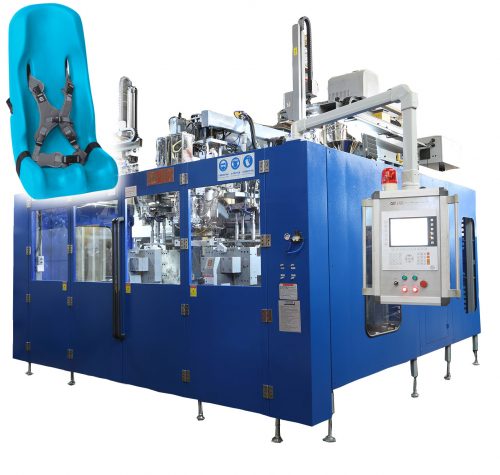

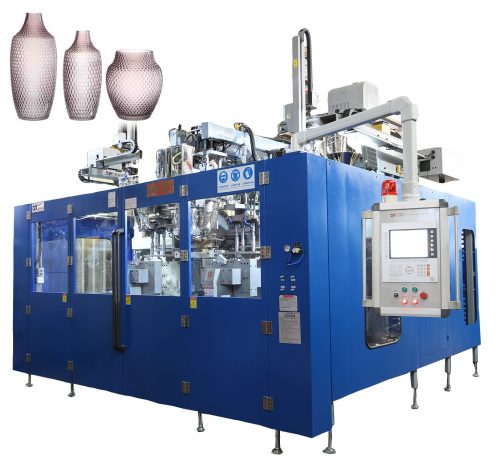

DKB-18L Blow Molding Machine With Full Automatic Packaging Production Line

DKB-18LD is normal Shuttle Blow Molding machine. Shuttle blow molding machine are used for the Extrusion Blow Molding (EBM) process. Shuttle machines are either single-sided or dual-sided machines, and can be manufactured to produce one- to six-layer containers for cosmetic, pharmaceutical, food, and chemical applications.

The Shuttle Production Process

- The shuttle is brought under the flowhead, where a parison of plastic material is being constantly extruded. The mold closes and “shuttles” away from the flowhead

- The mold is then brought to the blow pins, which are then forced downward into the molds, helping to “calibrate” the necks while air is forced into the cavity to blow the container. The shuttle motion allows the bottles to be blown and cooled to the side, without interfering with the parisons, which are continually extruding from the flowhead

- In a dual-sided shuttle machine, the second shuttle mold is brought under the flowhead while the first set is being blown and cooled, doubling the machine’s output

The Shuttle Mold

Plastic bellows by blow molding machine

Shuttle machines may extrude single or multiple parisons, and are characterized by the number of parisons and the horizontal spacing between the parisons. For example, a “4×100” shuttle extrudes four parisons, spaced 100 mm between the centers. This would require a platen (for attaching the molds) greater in size than 400 mm, to accommodate the required mold width. The horizontal or angled shuttling distance is thus greater than 400 mm for a 4×100 shuttle machine. In general, shuttle machines up to 2×100 mm spacing are considered small machines; shuttles up to 6×100 mm spacing are considered mid-sized machines; shuttles larger than this are typically referred to as “long-stroke” machines.

Check this video on youtube to see how tis DKB-18LD blow molding machine works:

Typically used for lower volume output, these machines generally have two to four cavities per mold, positioned horizontally next to each other. Key advantages of the shuttle blow molding process includes:

- Low mold cost for low volume output

- Capable of producing high-quality “calibrated neck” finish with blow pins

- In-machine trimming – finished bottles exit the machine

- Capable of producing handleware bottles

- Capable of producing multi-layer bottles (up to 6 layers)

Features for DKB-18LD:

- Double Station

- Single/Double/Triple/Q.12 Head

- Horizontal Operated Clamping System

- Production Volume:2ml~18L

- Multi layers: Co-Extrusion 1-6 Layers

- Multi cavities: 1~12 cavities

- Specialize for the PE/PP/PETG/PVC/Nylon/Co-Extrusion material

- Special function: View Stripe

- Clamping system: Toggle/3 Tie Bar/4 Tie Bar

- Driven Model: Hybrid servo motor drive system/ High performance hydraulic power saving system/Close loop proportional valve

- Support Parison controller/Auto Deflashing/Auto Recycling/Auto material feeder/Remote trouble shooting funciton/IML(in mold labeling)

Advantages

- Clamp sizes / quantity to match all requirements

- Easily configured for monolayer and multi-layer applications

- Single or multi parison

- Efficient electric drive(s) on extrusion system

- Low profile for ease of operator access

- Part removal and trimming matched to the application

- In-mold labeling and view stripe capable

- Lowest investment cost for high-speed applications

- Extreme bottle quality consistency

DKB-18L blow molding machine with full automatic packaging production line

Double formwork, single or double head.

The center is 250-280 mm from the double head and 180 mm on the three ends.

Single to six heads, optional transparent line function device.

Daily production capacity of 24 hours, 0.3 million -10,000

Can produce 5-18L hollow products.