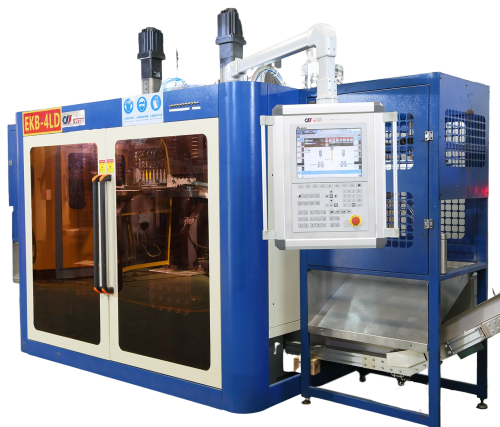

Full-automatic urea tank production line for diesel exhaust fluid (DEF) or AdBlue

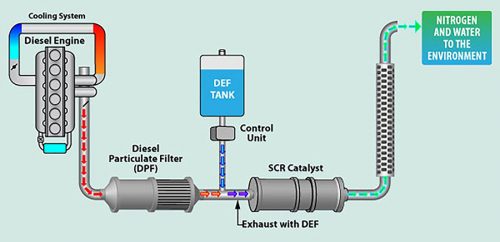

Diesel Exhaust Fluid (DEF) systems are used to supply Selective Catalytic Reduction (SCR) systems with a catalyst compound to

Full-automatic urea tank production line

break down harmful NOx emissions into nitrogen gas and water vapor. These systems are the preferred method for on-road and off-road

diesel vehicles and equipment users to meet increasingly strict emissions standards. Shaw manufactures eight standard cross-link.

This Full automatic production line is special for various urea tanks on diesel exhaust fluid(DEF)or AdBlue. The Urea Tank System is a convenient, fully packaged system for selective catalytic reduction (SCR) technology. With a range of urea tanks and header assemblies equipped with required sensors, the Urea Tank System portfolio assemblies also fulfill the installation needs of many applications with a broad range of urea lines. The Urea Tank System has an improved urea filtration capability to capture any foreign debris which may enter the urea holding chamber.

Usage of Urea Tanks

JinJun urea tanks are used with construction equipment and agricultural equipment, as well as trucks and buses, which have to comply with

increasingly tougher exhaust emission limits as a result of statutory provisions.

JinJun urea tanks are an important system component when it comes to meeting diesel exhaust emission regulations. For trucks and buses

these are Euro 6 in Europe, and EPA 2010 in the USA; for agricultural and construction equipment and other off-road vehicles Stage IIIB,

Stage IV and Stage V in Europe, and Tier 4 final in the USA.

In order to comply with these limits the SCR technology (selective catalytic reduction) is used in the majority of cases; here an aqueous urea solution

is metered into the exhaust gas stream. The urea decomposes to ammonia, with which the nitrogen oxides can be reduced on the SCR catalyst.

This chart explains how DEF diesel exhaust fluid works:

diesel exhaust fluid key diagram

The urea solution is known in Europe as AdBlue®, in the USA the expression DEF (for diesel emission fluid or diesel exhaust fluid) is generally used.

Due to the strongly corrosive properties of the urea solution urea tanks are generally manufactured using non-corrosive plastics. The only alternative material to this is stainless steel.

JinJun urea tanks manufactured from linear polyethylene

JinJun urea tanks are generally manufactured from linear polyethylene (PE); in rare cases crosslinked polyethylene (XPE) is also used.

As the aqueous urea solution freezes at -11°C (12°F), heatable tanks are necessary. In the design of urea tanks the freezing and thawing properties have to be taken into account. We can provide you with competent advice here.

JinJun can offer proven integrated tank heating concepts to thaw the urea solution, and which allow the heating geometry to be adapted to

the tank shape in an ideal manner. Should this not be necessary for your project, JinJun urea tanks can alternatively be fitted with connectors

that are fully compatible with the combined heating and extraction units (urea header units) from leading manufacturers.