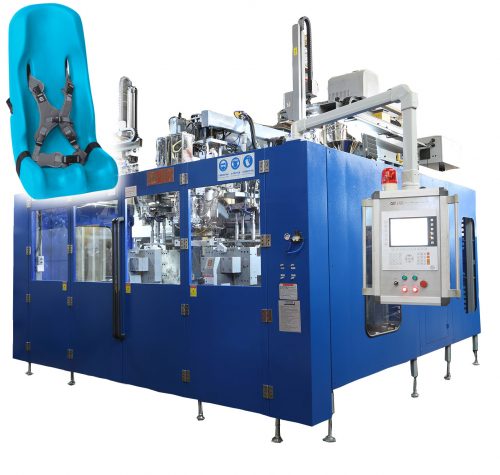

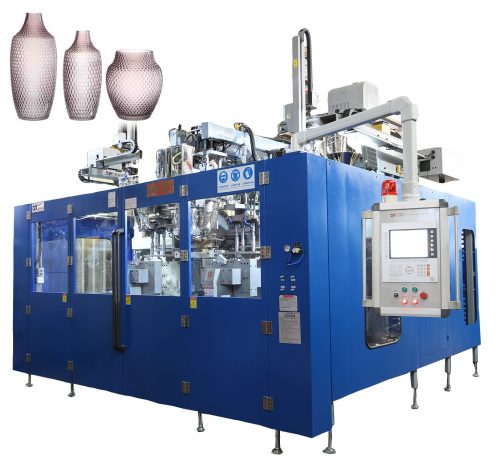

SUPER JINJUN DKB-2.5L EBM MACHINE FOR ELASTIC SOFT-TOUCH COSMETIC BOTTLE

This special designed low molding machine is used to make cosmetic bottles or other jars, and other hollow objects with soft touch and elastic surface, The process is similar to the old art of glass blowing and is a batch process. The inflated parison takes the shape of the mold and retains it upon cooling. The resulting products are tough, lightweight, and have large volume-to-weight ratio. Products range from simple radially symmetric bottles to complex items with handles or sculpted surfaces. Common examples are milk jugs, gas cans, shampoo containers, liquid storage tanks, toys, ducts, water bottles, and soda bottles. as we all know, soft touch is so cute, girls and boys like it, so cosmetic products with this soft touch looking bottles are always populared on the market. dual rayer bottle, means there are 2 extrusion syestem on it, 1 for PE or PP body material. and the other extrusion system is for this soft touch outlooking layer on the surface.

The machine features as below:

- Clamp sizes / quantity to match all requirements on soft touch bottle

- Easily configured for monolayer and multi-layer applications, it’s required for this soft touch bottle

- Single or multi parison, with high production capacity on the soft touch bottle.

- 2 efficient electric drive(s) on extrusion systems

- Low profile for ease of operator access

- Part removal and trimming matched to the application, it is not necessary on produciton of soft touch bottle

- In-mold labeling and view stripe capable

- Lowest investment cost for high-speed applications

- Extreme bottle quality consistency

DKB-2.5LD for soft touch cosmetic bottle is the model machine that suitable for cosmetic bottle, health care and toy etc. plastic products below 2.5L. Multi-die head with view strip line is optional. It can also connect with the IML machine. Auto de-flashing system and conveyor are optional to meet automatic production line. The daily output (24hrs) is approx. 12000-86000pcs.

Check the video to see how the machine works on dual layer soft touch cosmetic bottle production: