HOW BIG IS EPET’S POTENTIAL?

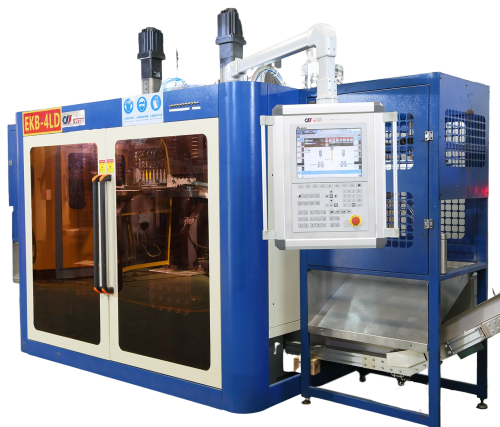

EPET is the largest Chance for Extrusion blow molding machine (EBM) business.High clarity, easy incorporation of handles, and recycling resin code No. 1. clear handleware containers are growing popularity, especially for orange and other juices,One recent success story for EPET has been orange juice, such as Simply Orange, a Coca-Cola Co. brand. EPET grades for EBM with hang strength, toughness, and reduced crystallization rates.

opportunities in large handleware (greater than 60 fl oz), particularly in dishwashing and laundry detergents. Agricultural chemicals and automotive fluids also beckon. Non-handleware applications include wide-mouth jars and some narrow-neck bottles. Non-handled, wide-mouth jars of various shapes and sizes These include jars for jams and jellies; liquor flasks of 100, 200, and 375 ml; and tall wide-mouth jars. He also points to future opportunities in personal care (health and beauty aids), nutritional supplements, pharmaceuticals, and niche food and beverage products. epet containers in juice, tea, nectar, water, olive oil and laundry detergents. He says the initial applications were juice and tea in containers with handles. The newer applications are household, food and water packaging.

opportunities in large handleware (greater than 60 fl oz), particularly in dishwashing and laundry detergents. Agricultural chemicals and automotive fluids also beckon. Non-handleware applications include wide-mouth jars and some narrow-neck bottles. Non-handled, wide-mouth jars of various shapes and sizes These include jars for jams and jellies; liquor flasks of 100, 200, and 375 ml; and tall wide-mouth jars. He also points to future opportunities in personal care (health and beauty aids), nutritional supplements, pharmaceuticals, and niche food and beverage products. epet containers in juice, tea, nectar, water, olive oil and laundry detergents. He says the initial applications were juice and tea in containers with handles. The newer applications are household, food and water packaging.

- Brands have begun to encourage EPET use by reducing their performance specs—notably in drop impact. If you have a secure handle, the container is less likely to drop.

• EPET has melting properties similar to stretch-blow PET resins.

• EPET crystallizes, so it can be reprocessed in standard PET crystallizing and drying equipment.

• EBM tooling is typically less expensive than preform injection and blow tooling for the PET stretch-blow molding process.