Lip gloss is a cosmetic used primarily to give lips a glossy luster, and sometimes to add a subtle color. It is distributed as a fluid or a soft solid (not to be confused with lip balm, which generally has medical or soothing purposes, or lipstick, which generally is a solid, cream-like substance that gives off a more pigmented color.) The product is available in ranges of opacity from translucent to solid and can have variously frosted, glittery, glossy, and metallic finishes.

Mascara is a cosmetic commonly used to enhance the upper and lower eyelashes. It is used to darken, thicken, lengthen, and/or define the eyelashes. Normally in one of three forms—liquid, powder, or cream—the modern mascara product has various formulas; however, most contain the same basic components of pigments, oils, waxes, and preservatives. The most common form of mascara is a liquid in a tube with an application brush.

Lip gloss (lip glaze) or mascara are all kind of liquid filled in a small tube or bottle. This bottle can be full transparent or translucent or opaque. How to produce lip gloss or lip glaze or mascara in factory? 3 steps you need to do:

Step 1, Formulaing and mix the lip gloss glaze or mascara

This would be easy if you got the formulation for lip gloss, it is just a simple weghting and mixing. no any questions.

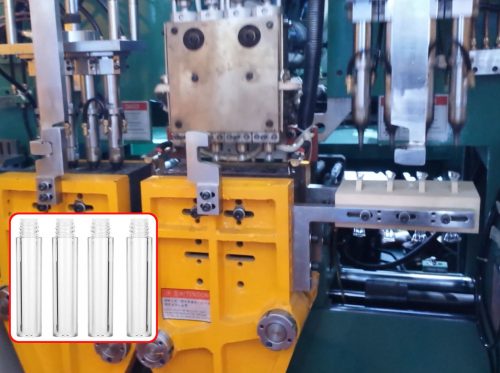

Step 2, Making tubes or bottles for this lip gloss glaze or mascara

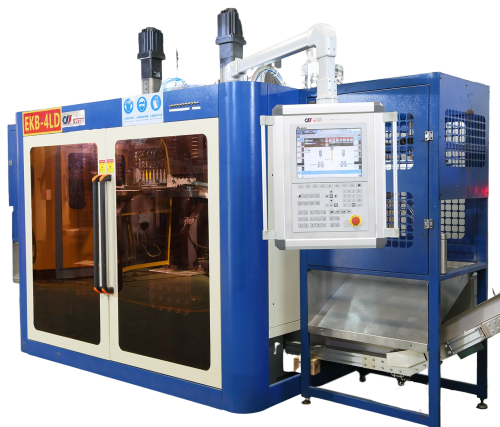

To making any plastic tubes or bottles, a blow molding machine is a must.

Step 2, filling the lip gloss or glaze or mascara and capping

As you know, lip gloss lip glazeor mascara are just a kind of liquid, it can be filled by a liquid filling machine. but as all these lip gloss or mascara bottles or tubes are too small in size,the bottles or tubes can no stand stable by itself, so this filling machine should be special designed.

Check this video, to see how to produce this lip gloss or lip glaze or mascara including bottle making, filling, capping: