Leaking detector on extrusion blow molding production line with INfrared Sensor

Feautures

1. High precision, can detect tiny leaks

2. Non-destructive detection, no harm to the products being tested

3. Better flexibility, one leak tester can test different products

4. PLC control, can store recipe for fast changeover

5. Colorful touch screen makes the operation fast and convenient

6. Can work independently or in line with the blow molding machine

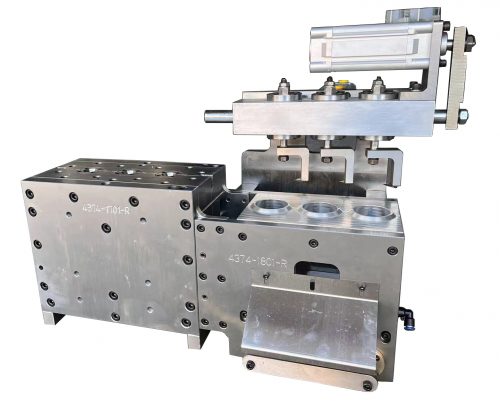

Double heads precision leak tester, model: PG-2

The double-head precision leaking detector PG-2 adopts PLC controlling system which enhances the flexibility of function extensions. The man-machine interface touch screen makes the operation simple and fast.

Detecting speed: 900 to 2000 bottles per hour

Conveyor length: 1500 mm

Conveyor height adjustment: 750mm to 1200 mm

Machine dimensions: 1500*700*1650 mm