Dental air/water syringes are a staple piece of equipment used during routine dental cleanings. Disposable dental air/water syringe tips are a safe and reliable alternative to traditional metal tips. Disposable air/water syringe tips offers a sterile option that helps minimize air and water crossover. Dentsply Sirona is a dedicated leader in dental infection prevention and control. We aim to curb the spread of infectious diseases in dental practices by offering high quality disposable products our customers can rely on.

Dental air/water syringes are a staple piece of equipment used during routine dental cleanings. Disposable dental air/water syringe tips are a safe and reliable alternative to traditional metal tips. Disposable air/water syringe tips offers a sterile option that helps minimize air and water crossover. Dentsply Sirona is a dedicated leader in dental infection prevention and control. We aim to curb the spread of infectious diseases in dental practices by offering high quality disposable products our customers can rely on.

There are long-term use air water syringe tip and disposable air water syringe tip. traditional metal tip is this long term use air water syringe tip.

So, why should people take this disposable air water syringe tip?

Scientific studies done by multiple groups have shown that even when metal air water syringe tips are put through multiple sterilization cycles (standard dental offices put metal air water syringe tips through 1 cycle), of the tips tested, 10% still contain live active bacteria.

Now 1% would be enough to consider the sterilization cycle ineffective. But 10% is a shocking number for any type of device used for treatments where blood, saliva, and tissue are interacting. Over 20 years ago, after discovering metal air water syringe tips could not be properly sterilized, disposable (single-use) air water syringe tips were created as a safer alternative. The creation of single-use tips were suppose to eliminate dentists, orthodontists, and hygienists from using metal air water syringe tips. This is still not the case.

Disposable air water syringe tips are single-use tips that would be used as a replacement product for metal air water syringe tips. The purpose of disposable air water syringe tips was to eliminate cross-contamination and to ensure one tip was used on one patient. Once a disposable tip is used, it is then thrown away and a new tip would be used on the next patient.

As you can see, this kind of plastic Disposable Air Water Syringe Tips is hard to produce, it takes a few processes to finish.

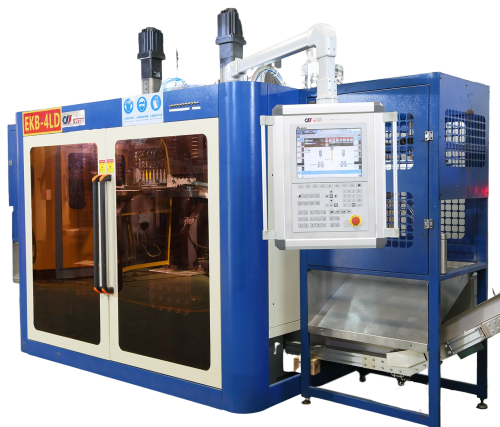

of course, it is not cheap. now a new plastic Disposable Air Water Syringe Tips is invented. it is made by extrusion blow molding machine. it is same as this:

It is made by blow molding only, no second processes. No other services. it is just simple and easy. it costs only a few pennies. and more important, the production for this blow molded plastic disposable air watersyringe tip. By this cheap single-used plastic air water syringe tip.

Traditional metal syringes are still considered by many to be an indispensable component to any dental health practice, but unfortunately, metal syringes hold many liabilities for even the most competent dental health practitioners and their clients. With the consistent risk of cross-contamination, the use of a metal syringe tips can often be time consuming, requiring constant sterilization that can still leave small but dangerous particles of infectious debris inside of the tip. With the risk of infection constantly looming, this routine sterilization prolongs the process, exhausting the health practitioner and the patient, decreasing customer satisfaction while increasing expenses.